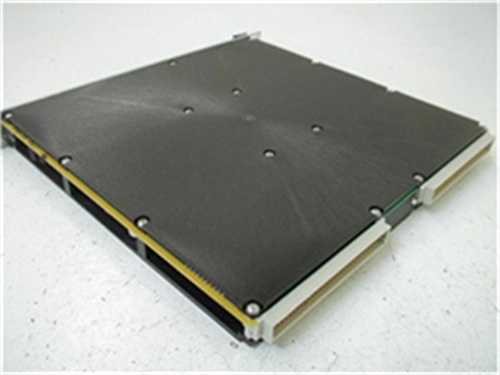

描述

WOODWARD 5464-538是伍德沃德(WOODWARD)公司为工业自动化系统设计的可编程逻辑控制器(PLC)模块,广泛应用于能源、电力、船舶及过程工业等领域。以下是其核心功能与技术特性:

1.核心功能

工业控制基础:

作为PLC核心模块,支持逻辑运算、定时、计数及算术运算,通过数字/模拟输入输出控制机械或生产过程,适用于工业场景的自动化管理。

实时时钟与小时表:

内置实时时钟功能,支持时间设置与比较指令,小时表功能可记录设备运行时间,便于维护与过程跟踪。

持续扫描与输入滤波:

定义操作周期的持续扫描时间,并通过输入滤波器调节功能平整输入信号(如X000-X017通道),减少噪声干扰。

2.技术参数

电源与接口:

支持交流电源或24V直流输入,兼容漏型继电器输出或晶体管输出(如Fx1n-40MR/MT型号)。

安全与权限管理:

提供密码保护功能,通过八位数字密码锁定程序,防止非授权访问。

3.故障诊断与维护

电源异常排查:

若电源灯不亮,需依次检查供电电压、熔丝状态及接线是否松动,必要时替换电源部件。

输入输出问题:

输入故障:通过LED指示器验证现场元件(如按钮、传感器)是否正常,检查输入端电压是否达标。

输出故障:若输出设备未响应,需检查保险丝、替换模块或验证现场接线是否正确。

指示器逻辑验证:

逻辑指示器与电源指示器需同步亮起以确认模块正常工作,若仅单个指示器亮起,可能为模块硬件故障。

4.技术优势

高可靠性:

采用工业级设计,支持宽温环境(-40℃至70℃),抗电磁干扰能力符合IEC 61000标准,MTBF超过50,000小时。

灵活扩展:

可与伍德沃德其他模块(如I/O扩展、通信模块)级联,构建分布式控制系统。

WOODWARD 5464-538 is a programmable logic controller(PLC)module designed by Woodward for industrial automation systems.It is widely used in energy,power,shipbuilding and process industries.The following are its core functions and technical features:

1.Core functions

Industrial control basics:

As a PLC core module,it supports logical operations,timing,counting and arithmetic operations,and controls machinery or production processes through digital/analog input and output,which is suitable for automated management of industrial scenarios.

Real-time clock and hour meter:

Built-in real-time clock function,supports time setting and comparison instructions,and the hour meter function can record the equipment running time for easy maintenance and process tracking.

Continuous scanning and input filtering:

Define the continuous scanning time of the operation cycle,and smooth the input signal(such as X000-X017 channels)through the input filter adjustment function to reduce noise interference.

2.Technical parameters

Power supply and interface:

Support AC power supply or 24V DC input,compatible with leakage relay output or transistor output(such as Fx1n-40MR/MT model).

Security and authority management:

Provide password protection function,lock the program with an eight-digit password to prevent unauthorized access.

3.Fault diagnosis and maintenance

Power supply abnormality troubleshooting:

If the power light is off,check the power supply voltage,fuse status and whether the wiring is loose,and replace the power supply component if necessary.

Input and output problems:

Input failure:Verify whether the on-site components(such as buttons and sensors)are normal through the LED indicator,and check whether the input voltage meets the standard.

Output failure:If the output device does not respond,check the fuse,replace the module or verify whether the on-site wiring is correct.

Indicator logic verification:

The logic indicator and the power indicator need to light up synchronously to confirm that the module is working properly.If only a single indicator lights up,it may be a hardware failure of the module.

4.Technical advantages

High reliability:

Adopting industrial-grade design,supporting wide temperature environment(-40℃to 70℃),anti-electromagnetic interference capability complies with IEC 61000 standards,and MTBF exceeds 50,000 hours.

Flexible expansion:

Can be cascaded with other Woodward modules(such as I/O expansion,communication modules)to build a distributed control system.