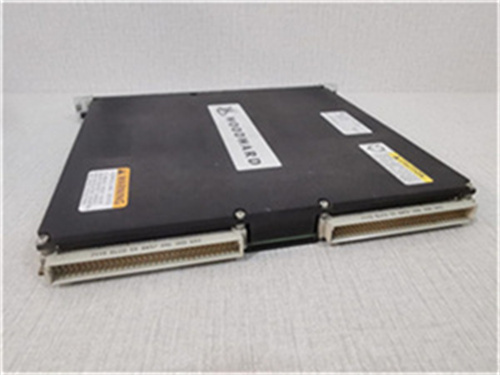

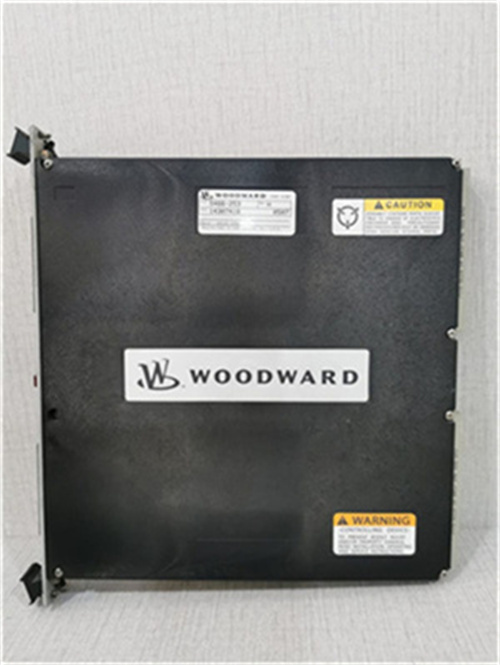

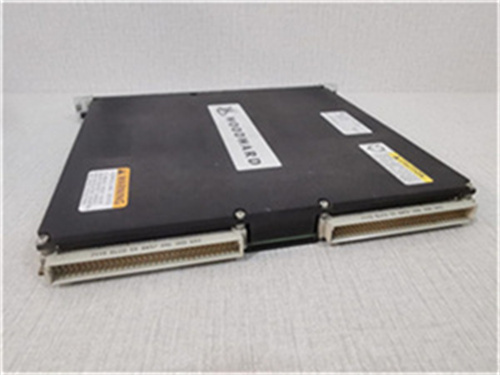

描述

WOODWARD 5466-033是伍德沃德(WOODWARD)公司开发的高性能调速控制器模块,适用于工业自动化系统的速率监测与控制。以下是其核心功能与技术特性:

1.核心功能

调速控制:

作为调速器核心模块,用于监测并控制发动机、涡轮机等设备的转速,确保其在设定范围内稳定运行,支持多通道速率监测与反馈调节。

PLC兼容性:

集成硬PLC架构(LD指令处理器),支持逻辑控制与数据运算,可与伍德沃德其他模块(如I/O扩展、通信模块)协同工作,构建分布式控制系统。

2.性能参数

工作电压:220V AC;

输出频率:6Hz(可定制调整);

处理速度:3Hz(指令执行响应时间);

存储容量:程序存储6MB,数据存储3MB;

环境适应性:工作温度-40℃至60℃,抗电磁干扰能力符合工业标准。

3.技术优势

高可靠性:

采用工业级元器件与冗余设计,MTBF超过50,000小时,支持在线故障诊断与自恢复功能。

灵活扩展:

支持RS-232/485、CAN总线及以太网接口,可与西门子、施耐德等主流工业设备无缝对接。

安全防护:

集成过压、过流保护模块,防止设备因异常工况损坏。

4.应用场景

能源电力:

控制燃气轮机、蒸汽轮机的转速,优化发电机组并网稳定性;

船舶工程:

驱动船舶发动机执行器,实现动态定位与航行控制;

石油化工:

调节压缩机、泵等设备的转速,优化工艺流程效率;

制造业:

精确控制机械臂、传送带等设备的速度,提升生产精度。

WOODWARD 5466-033 is a high-performance speed controller module developed by Woodward,suitable for speed monitoring and control of industrial automation systems.The following are its core functions and technical features:

1.Core functions

Speedcontrol:

As the core module of the speed regulator,it is used to monitor and control the speed of engines,turbines and other equipment to ensure stable operation within the set range,and supports multi-channel speed monitoring and feedback adjustment.

PLC compatibility:

Integrated hard PLC architecture(LD instruction processor),supports logic control and data calculation,and can work with other Woodward modules(such as I/O expansion,communication module)to build a distributed control system.

2.Performance parameters

Working voltage:220V AC;

Output frequency:6Hz(customizable);

Processing speed:3Hz(instruction execution response time);

Storage capacity:6MB for program storage,3MB for data storage;

Environmental adaptability:working temperature-40℃to 60℃,anti-electromagnetic interference capability meets industrial standards.

3.Technical advantages

High reliability:

Adopting industrial-grade components and redundant design,MTBF exceeds 50,000 hours,supporting online fault diagnosis and self-recovery functions.

Flexible expansion:

Supports RS-232/485,CAN bus and Ethernet interfaces,and can be seamlessly connected with mainstream industrial equipment such as Siemens and Schneider.

Safety protection:

Integrated overvoltage and overcurrent protection modules to prevent equipment from being damaged due to abnormal working conditions.

4.Application scenarios

Energy and power:

Control the speed of gas turbines and steam turbines to optimize the grid-connected stability of generator sets;

Ship engineering:

Drive ship engine actuators to achieve dynamic positioning and navigation control;

Petrochemical:

Adjust the speed of compressors,pumps and other equipment to optimize process efficiency;

Manufacturing:

Precisely control the speed of equipment such as robotic arms and conveyor belts to improve production accuracy.