描述

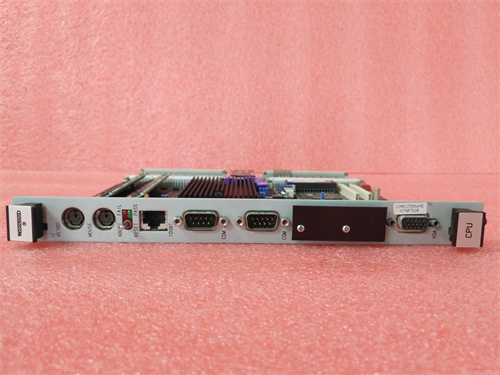

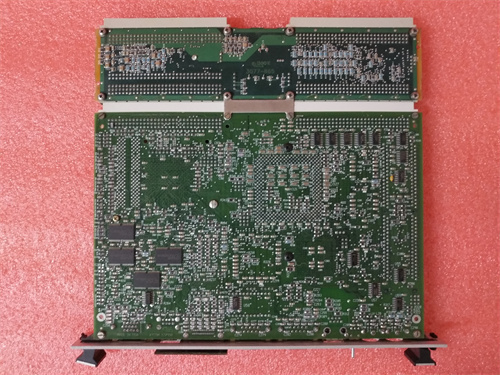

WOODWARD 5466-409是伍德沃德(WOODWARD)公司为工业自动化系统设计的核心控制模块,结合了高性能计算、精准速率控制及广泛兼容性,适用于能源、电力、船舶及过程工业等关键领域。以下是其核心功能与技术特性:

1.核心功能

速率监测与控制:

作为调速器控制主板卡,该模块能够实时监测发动机、涡轮机等设备的转速,并通过闭环控制确保其稳定运行,支持多通道速率输入与反馈调节。

工业控制中枢:

作为MicroNet系列的奔腾CPU模块,运行频率233MHz,配备64MB RAM,适用于单工系统,支持双RS-232串口及单以太网接口,实现高带宽数据传输。

PLC兼容性:

基于硬PLC架构(LD指令处理器),支持梯形图编程及数据存储,可与伍德沃德其他模块(如I/O扩展、通信模块)协同工作,构建分布式控制系统。

2.技术参数

工作温度:0℃至50℃,适用于工业环境;

I/O扩展能力:支持252点I/O(具体配置可定制);

通信协议:Modbus、RS-232/485、以太网;

电源:220V/380V AC(宽电压输入);

处理速度:3Hz(指令执行响应时间)。

3.技术优势

高可靠性:

采用工业级元器件与冗余设计,MTBF超过50,000小时,支持在线故障诊断与自恢复功能。

灵活性与定制性:

支持用户自定义控制参数(如转速偏置、运动模式),可通过AppManager工具实现远程配置与程序加载。

环境适应性:

通过CE认证,抗电磁干扰能力符合工业标准,适用于船舶、发电站等严苛场景。

4.应用场景

能源电力:

控制燃气轮机、蒸汽轮机的转速与负荷分配,优化发电机组并网稳定性;

船舶工程:

监测推进系统转速,实现动态定位与航行控制;

石油化工:

调节压缩机、泵等设备的转速,优化工艺流程效率;

制造业:

驱动机械臂、传送带等设备,实现精准速度控制。

WOODWARD 5466-409 is a core control module designed by Woodward for industrial automation systems.It combines high-performance computing,precise rate control and wide compatibility,and is suitable for key areas such as energy,power,shipping and process industries.The following are its core functions and technical features:

1.Core functions

Rate monitoring and control:

As a speed regulator control motherboard card,this module can monitor the speed of engines,turbines and other equipment in real time,and ensure its stable operation through closed-loop control,supporting multi-channel rate input and feedback adjustment.

Industrial control center:

As a Pentium CPU module of the MicroNet series,it runs at a frequency of 233MHz and is equipped with 64MB RAM.It is suitable for simplex systems and supports dual RS-232 serial ports and single Ethernet interfaces to achieve high-bandwidth data transmission.

PLC compatibility:

Based on the hard PLC architecture(LD instruction processor),it supports ladder diagram programming and data storage,and can work with other Woodward modules(such as I/O expansion,communication modules)to build distributed control systems.

2.Technical parameters

Operating temperature:0℃to 50℃,suitable for industrial environments;

I/O expansion capability:supports 252 points of I/O(specific configuration can be customized);

Communication protocol:Modbus,RS-232/485,Ethernet;

Power supply:220V/380V AC(wide voltage input);

Processing speed:3Hz(instruction execution response time).

3.Technical advantages

High reliability:

Adopting industrial-grade components and redundant design,MTBF exceeds 50,000 hours,supporting online fault diagnosis and self-recovery functions.

Flexibility and customization:

Supports user-defined control parameters(such as speed bias,motion mode),and can realize remote configuration and program loading through the AppManager tool.

Environmental adaptability:

CE certified,anti-electromagnetic interference capability meets industrial standards,suitable for harsh scenarios such as ships and power stations.

4.Application scenarios

Energy and power:

Control the speed and load distribution of gas turbines and steam turbines,and optimize the grid-connected stability of generator sets;

Ship engineering:

Monitor the speed of propulsion systems to achieve dynamic positioning and navigation control;

Petrochemical:

Adjust the speed of compressors,pumps and other equipment to optimize process efficiency;

Manufacturing:

Drive robotic arms,conveyor belts and other equipment to achieve precise speed control.