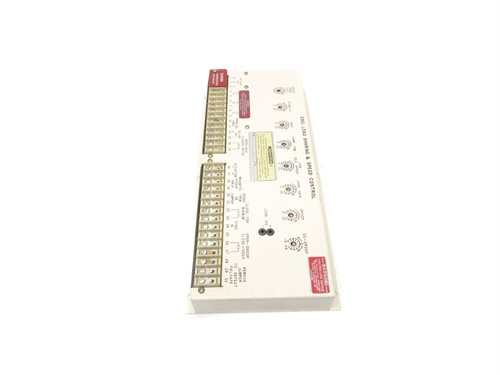

描述

WOODWARD 8271-467是伍德沃德(WOODWARD)公司为工业自动化系统设计的核心控制模块,兼具电源管理与逻辑控制功能,广泛应用于能源、电力、船舶及智能制造等领域。以下是其核心功能与技术特性:

1.核心功能

工业电源与控制器双重角色:

该模块既是工业电源,提供24V直流电以支持PLC、DCS等控制系统运行,同时具备模块卡件控制器功能,负责逻辑运算、输入输出管理及数据处理。

负载分担与速度控制:

通过集成PID算法,可实现电机或设备的转速调节与负载分配,适用于调速器、驱动系统等场景,响应速度达毫秒级。

现场总线兼容性:

支持Modbus、CAN总线等工业协议,可与现场仪表、传感器等设备无缝通信,减少传统接线复杂度。

2.技术参数

电气性能:

工作电压180V,输出频率1700Hz,支持-10℃至50℃宽温环境,抗电磁干扰能力符合工业标准。

I/O扩展:

输入/输出点数各1300点,支持多通道扩展,满足复杂控制系统需求。

存储与运算:

集成EEPROM存储器,可存储用户程序及重要数据,支持逻辑运算、计时、代数运算等复杂计算功能。

3.运算与控制能力

基础功能:

提供逻辑运算(与、或、非等)、计时、计数等基础PLC功能,适用于简单控制逻辑。

高级功能:

支持代数运算、数据传送及PID闭环控制,可处理模拟量信号,实现对温度、压力等参数的高精度调节。

编程兼容性:

支持梯形图、指令表等编程语言,兼容西门子、施耐德等主流PLC系统。

4.应用场景

能源与电力:

控制燃气轮机、发电机的转速与负荷分配,优化发电效率。

船舶工程:

驱动推进系统电机,实现动态定位与航行控制。

智能制造:

驱动机械臂、传送带等设备,实现精准速度控制及故障诊断。

过程工业:

精确控制压缩机、泵等设备的运行状态,优化工艺流程稳定性。

WOODWARD 8271-467 is a core control module designed by Woodward for industrial automation systems.It has both power management and logic control functions and is widely used in energy,electricity,ships,and intelligent manufacturing.The following are its core functions and technical features:

1.Core functions

Dual roles of industrial power supply and controller:

This module is both an industrial power supply,providing 24V DC to support the operation of control systems such as PLC and DCS,and has the function of module card controller,responsible for logic operations,input and output management and data processing.

Load sharing and speed control:

Through the integrated PID algorithm,the speed regulation and load distribution of the motor or equipment can be realized.It is suitable for scenes such as speed regulators and drive systems,and the response speed reaches milliseconds.

Fieldbus compatibility:

Supports industrial protocols such as Modbus and CAN bus,and can communicate seamlessly with field instruments,sensors and other equipment,reducing the complexity of traditional wiring.

2.Technical parameters

Electrical performance:

Working voltage 180V,output frequency 1700Hz,supports wide temperature environment from-10℃to 50℃,and anti-electromagnetic interference capability meets industrial standards.

I/O expansion:

Input/output points are 1300 points each,supporting multi-channel expansion to meet the needs of complex control systems.

Storage and calculation:

Integrated EEPROM memory can store user programs and important data,and supports complex calculation functions such as logical operations,timing,and algebraic operations.

3.Calculation and control capabilities

Basic functions:

Provides basic PLC functions such as logical operations(AND,OR,NOT,etc.),timing,and counting,suitable for simple control logic.

Advanced functions:

Supports algebraic operations,data transmission and PID closed-loop control,can process analog signals,and achieve high-precision adjustment of parameters such as temperature and pressure.

Programming compatibility:

Supports programming languagessuch as ladder diagrams and instruction tables,and is compatible with mainstream PLC systems such as Siemens and Schneider.

4.Application scenarios

Energy and electricity:

Control the speed and load distribution of gas turbines and generators to optimize power generation efficiency.

Ship engineering:

Drive the propulsion system motor to achieve dynamic positioning and navigation control.

Smart manufacturing:

Drive mechanical arms,conveyor belts and other equipment to achieve precise speed control and fault diagnosis.

Process industry:

Precisely control the operating status of compressors,pumps and other equipment to optimize process stability.