描述

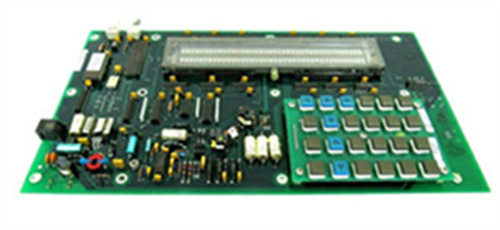

Woodward 8444-1067是一款高性能模拟量输出模块,专为工业自动化、电力系统、过程控制及机械控制等领域设计,通过精确的转矩控制实现高效设备运行。以下是其核心功能与技术特点的综合解析:

一、产品概述

该模块属于Woodward系列PLC/DCS系统的核心组件,主要用于连接传感器、执行器(如电机、阀门)和控制设备,实现自动化生产和过程控制。其模拟量输出功能可将数字信号转换为连续的模拟信号,支持对设备运行参数(如转速、转矩)的精准调节。

二、技术特点

变速控制技术

采用转矩不变技术和转矩恒速技术,通过动态调整电机转矩实现速度控制,适用于需要稳定转矩输出的场景(如发电机、变压器控制)。

能够保持电机转速与转矩的一致性,但需注意效率可能因控制策略而略有降低。

工业级可靠性

兼容严苛工业环境(如高温、高湿度),支持长时间连续运行。

支持现场总线协议(如RS-485),便于集成到DCS/PLC系统中。

模块化设计

可灵活扩展,适用于小型自动化设备或大规模分布式控制系统。

三、核心功能

模拟量输出能力

提供高精度模拟信号输出,支持与传感器、执行器的无缝对接。

支持多通道输出,满足复杂控制系统需求。

智能接口

支持以太网、RS-232/485等通信协议,可与上位机或控制器实时交互。

四、典型应用场景

工业自动化

在生产线上监控设备状态,优化工艺流程,确保稳定运行。

电力系统

用于发电机、变压器等设备的转矩和转速控制,保障电力系统稳定性。

过程控制

化工、石油、天然气等行业的工艺参数监测与调节(如温度、压力)。

机械控制

精确控制机械系统的运动部件(如阀门、马达),提升设备精度。

Woodward 8444-1067 is a high-performance analog output module designed for industrial automation,power systems,process control and mechanical control.It achieves efficient equipment operation through precise torque control.The following is a comprehensive analysis of its core functions and technical features:

I.Product Overview

This module is a core component of the Woodward series PLC/DCS system.It is mainly used to connect sensors,actuators(such as motors,valves)and control equipment to achieve automated production and process control.Its analog output function can convert digital signals into continuous analog signals,supporting precise adjustment of equipment operating parameters(such as speed and torque).

II.Technical Features

Variable speed control technology

Using torque-invariant technology and torque-constant speed technology,speed control is achieved by dynamically adjusting the motor torque,which is suitable for scenarios that require stable torque output(such as generator and transformer control).

It can maintain the consistency of motor speed and torque,but it should be noted that the efficiency may be slightly reduced due to the control strategy.

Industrial-grade reliability

Compatible with harsh industrial environments(such as high temperature and high humidity),supporting long-term continuous operation.

Supports fieldbus protocols(such as RS-485)for easy integration into DCS/PLC systems.

Modular design

Flexibly expandable,suitable for small automation equipment or large-scale distributed control systems.

III.Core functions

Analog output capability

Provides high-precision analog signal output and supports seamless connection with sensors and actuators.

Supports multi-channel output to meet the needs of complex control systems.

Intelligent interface

Supports communication protocols such as Ethernet and RS-232/485,and can interact with the host computer or controller in real time.

IV.Typical application scenarios

Industrial automation

Monitor equipment status on the production line,optimize process flow,and ensure stable operation.

Power system

Used for torque and speed control of equipment such as generators and transformers to ensure the stability of the power system.

Process control

Monitoring and adjusting process parameters(such as temperature and pressure)in industries such as chemical,petroleum,and natural gas.

Mechanical control

Precisely control the moving parts of mechanical systems(such as valves and motors)to improve equipment accuracy.