描述

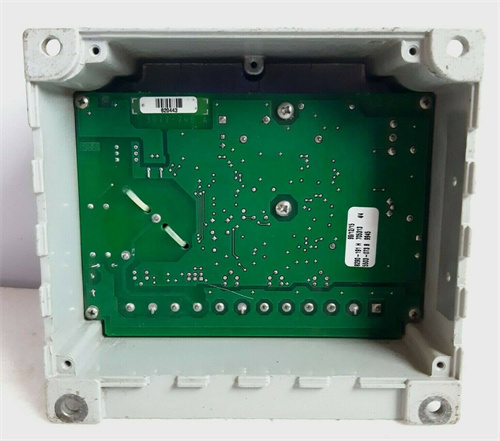

Woodward 8446-1019产品详情

一、基本信息

品牌:Woodward(伍德沃德,全球工业控制与能源管理领域的领导者,专注于发动机、涡轮机、发电机组的电子控制系统和执行器)

型号:8446-1019

类型:数字式速度控制器(Digital Speed Controller),属于Woodward的ProTech系列或工业调速器产品线,专为柴油机、燃气发动机、蒸汽涡轮机等旋转机械设计。

用途:用于精确控制发动机或涡轮机的转速,确保其在负载变化或环境干扰下保持稳定运行,广泛应用于发电、船舶推进、石油天然气压缩、工业泵/风机驱动等领域。

二、技术规格

1.核心功能

控制模式:

速度控制:通过PID算法调节燃油/燃气供应,维持设定转速(如1500rpm、1800rpm)。

负载分配:支持多台机组并联运行时的负载均衡(需配合Woodward的同步器或负载共享模块)。

启动/停机控制:可编程的启动曲线(如斜坡升速)和安全停机逻辑。

输入信号:

转速反馈:支持磁电式转速传感器(如Woodward 2600系列)、脉冲信号或编码器输入。

模拟量输入:可接收外部设定值(如4~20mA)或远程调速信号。

数字量输入:用于启动/停机命令、故障复位等。

输出信号:

执行器驱动:提供0~135Ω电位计信号或4~20mA电流信号,驱动Woodward的UG系列或EG系列执行器。

报警与状态输出:干接点或继电器输出,用于超速、低速、传感器故障等报警。

2.性能参数

转速控制精度:±0.1%以内(稳态),响应时间≤100ms(动态)。

调速范围:50~18000rpm(取决于传感器类型与执行器能力)。

超速保护:可配置两级超速保护(如110%额定转速报警,115%紧急停机)。

环境适应性:

工作温度:-40℃至+70℃(工业级宽温设计)。

防护等级:IP20(控制柜内安装),抗振动与冲击符合MIL-STD-810标准。

3.通信与接口

通信协议:支持Modbus RTU(RS-485)、CANopen或Woodward专有协议,便于与上位机或SCADA系统集成。

人机界面:

本地显示:LED指示灯(运行、故障、通信状态)。

可选配液晶显示屏(如8446-1019-LCD型号),实时显示转速、设定值、故障代码等。

编程接口:通过Woodward的ToolKit软件配置参数(如PID增益、启动曲线、报警阈值)。

三、产品优势

高可靠性与冗余设计

冗余传感器输入:支持双转速传感器输入,自动切换以避免单点故障。

硬件看门狗:内置自检功能,故障时自动切换至安全状态。

电磁兼容性(EMC):符合IEC 61000-6标准,抗干扰能力强。

灵活配置与易用性

参数可编程:通过ToolKit软件快速配置控制逻辑、报警阈值、通信参数等。

多语言支持:软件界面支持英文、中文、德文等,便于全球用户操作。

模块化设计:可扩展I/O模块(如增加模拟量输入/输出),适应不同应用需求。

兼容性与认证

兼容Woodward全系列执行器(如UG-8、EG-3P)和转速传感器。

符合CE、UL、cUL、ATEX(防爆认证,可选)等国际标准,适用于危险区域。

四、应用场景

发电与分布式能源

柴油发电机组:控制转速以维持电网频率稳定(如50Hz/60Hz)。

燃气轮机发电:与Woodward的MicroNet TMR控制器配合,实现三重冗余控制。

船舶与海洋工程

主推进系统:控制船用柴油机或燃气轮机的转速,确保航行稳定性。

辅助发电机:在船舶电网中维持负载平衡。

石油天然气

压缩机驱动:控制天然气压缩机的转速,优化能效并避免喘振。

泵驱动:调节注水泵或输油泵的流量(通过转速控制)。

工业驱动

风机与泵:通过变频调速或Woodward调速器实现节能控制。

测试台架:在发动机或涡轮机测试中精确控制转速与负载。

Woodward 8446-1019 Product Details

I.Basic Information

Brand:Woodward(a global leader in industrial control and energy management,focusing on electronic control systems and actuators for engines,turbines,and generator sets)

Model:8446-1019

Type:Digital SpeedController,a member of Woodward’s ProTech series or industrial speed regulator product line,designed for rotating machinery such as diesel engines,gas engines,and steam turbines.

Use:Used to accurately control the speed of an engine or turbine to ensure stable operation under load changes or environmental interference.It is widely used in power generation,ship propulsion,oil and gas compression,industrial pump/fan drive and other fields.

II.Technical Specifications

1.Core Functions

Control Mode:

Speedcontrol:Regulate fuel/gas supply through PID algorithm to maintain a set speed(such as 1500rpm,1800rpm).

Load distribution:Supports load balancing when multiple units are running in parallel(need to be used with Woodward’s synchronizer or load sharing module).

Start/Stop Control:Programmable start curve(such as ramp speed increase)and safety shutdown logic.

Input signal:

Speedfeedback:Supports magnetic speed sensor(such as Woodward 2600 series),pulse signal or encoder input.

Analog input:Can receive external set value(such as 4~20mA)or remote speed control signal.

Digital input:Used for start/stop command,fault reset,etc.

Output signal:

Actuator drive:Provides 0~135Ωpotentiometer signal or 4~20mA current signal to drive Woodward’s UG series or EG series actuators.

Alarm and status output:Dry contact or relay output for alarms such as overspeed,underspeed,sensor failure,etc.

2.Performance parameters

Speedcontrol accuracy:within±0.1%(steady state),response time≤100ms(dynamic).

Speedrange:50~18000rpm(depending on sensor type and actuator capacity).

Overspeed protection:Two levels of overspeed protection can be configured(such as 110%rated speed alarm,115%emergency shutdown).

Environmental adaptability:

Operating temperature:-40℃to+70℃(industrial wide temperature design).

Protection level:IP20(installed in the control cabinet),vibration and shock resistance meet MIL-STD-810 standards.

3.Communication and interface

Communication protocol:Support Modbus RTU(RS-485),CANopen or Woodward proprietary protocol,easy to integrate with the host computer or SCADA system.

Human-machine interface:

Local display:LED indicator(running,fault,communication status).

Optional LCD display(such as 8446-1019-LCD model)to display speed,set value,fault code,etc.in real time.

Programming interface:Configure parameters(such as PID gain,startup curve,alarm threshold)through Woodward’s ToolKit software.

III.Product advantages

High reliability and redundant design

Redundant sensor input:Support dual speed sensor input,automatic switching to avoid single point failure.

Hardware watchdog:built-in self-check function,automatically switches to a safe state when a fault occurs.

Electromagnetic compatibility(EMC):complies with IEC 61000-6 standards and has strong anti-interference ability.

Flexible configuration and ease of use

Parameter programmability:quickly configure control logic,alarm thresholds,communication parameters,etc.through ToolKit software.

Multi-language support:the software interface supports English,Chinese,German,etc.,which is convenient for global users to operate.

Modular design:expandable I/O modules(such as adding analog input/output)to meet different application requirements.

Compatibility and certification

Compatible with Woodward’s full range of actuators(such as UG-8,EG-3P)and speed sensors.

Complies with international standards such as CE,UL,cUL,ATEX(explosion-proof certification,optional),suitable for hazardous areas.

IV.Application scenarios

Power generation and distributed energy

Diesel generator sets:control the speed to maintain a stable grid frequency(such as 50Hz/60Hz).

Gas turbine power generation:cooperate with Woodward’s MicroNet TMR controller to achieve triple redundant control.

Marine and Offshore

Main Propulsion:Control the speed of marine diesel engines or gas turbines to ensure navigation stability.

Auxiliary Generators:Maintain load balance in the ship’s power grid.

Oil and Gas

Compressor Drives:Control the speed of natural gas compressors to optimize energy efficiency and avoid surge.

Pump Drives:Regulate the flow of water injection pumps or oil transfer pumps(through speed control).

Industrial Drives

Fans and Pumps:Energy-saving control through variable frequency speed regulation or Woodward speed regulators.

Test Benches:Precisely control speed and load during engine or turbine testing.