描述

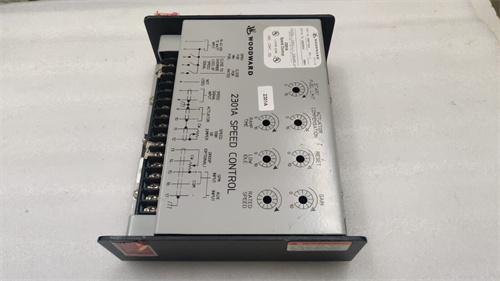

WOODWARD 9907-014是伍德沃德(WOODWARD)公司为工业自动化系统设计的核心控制模块,属于2301A系列速度控制器,广泛应用于发电、船舶、工业制造及能源等领域。以下是其综合技术特性与应用场景分析:

1.核心功能

速度与位置控制:

作为电控液压放大器,该模块可将电控制信号转化为液压输出,驱动执行机构实现精准速度调节与位置控制,适用于汽轮机、发动机等高负载场景。

多协议兼容性:

支持Modbus、DNP3、Profibus、Ethernet/IP等通讯协议,可与DCS、PLC等系统无缝集成,实现远程监控与参数调整。

2.技术参数

控制范围:

支持500-1500Hz、1000-3000Hz或2000-6000Hz的额定转速范围,覆盖不同工况需求。

电源要求:

低压型号需20-40Vdc直流电源,高压型号支持90-150Vdc或88-132Vac电源输入。

执行器电流:

提供三种电流范围型号,适用于不同负载场景。

3.应用场景

发电行业:

控制燃气轮机或柴油发电机转速,确保发电输出稳定。

船舶与海洋工程:

调节船舶发动机转速,实现动态定位与航行控制。

工业制造:

应用于压缩机、泵等设备,优化工艺流程效率。

石油天然气:

控制钻井设备转速,保障作业稳定性。

4.技术优势

高精度控制:

采用PID算法与微分增益调整技术,超调量低且响应速度快,控制精度达±0.5%。

灵活扩展:

可与伍德沃德2301、500系列或NetCon控制器配套使用,支持分布式控制系统架构。

可靠性设计:

通过ISO 9001认证,平均无故障时间(MTBF)超50,000小时,适应高温、高振动工业环境。

WOODWARD 9907-014 is a core control module designed by Woodward for industrial automation systems.It belongs to the 2301A series speed controller and is widely used in power generation,shipbuilding,industrial manufacturing and energy.The following is an analysis of its comprehensive technical characteristics and application scenarios:

1.Core functions

Speedand position control:

As an electric-controlled hydraulic amplifier,this module can convert electrical control signals into hydraulic outputs,drive actuators to achieve precise speed regulation and position control,and is suitable for high-load scenarios such as steam turbines and engines.

Multi-protocol compatibility:

Supports communication protocols such as Modbus,DNP3,Profibus,Ethernet/IP,etc.,and can be seamlessly integrated with DCS,PLC and other systems to achieve remote monitoring and parameter adjustment.

2.Technical parameters

Control range:

Supports rated speed ranges of 500-1500Hz,1000-3000Hz or 2000-6000Hz,covering different working conditions.

Power requirements:

Low voltage models require 20-40Vdc DC power supply,high voltage models support 90-150Vdc or 88-132Vac power input.

Actuator current:

Three current range models are available for different load scenarios.

3.Application scenarios

Power generation industry:

Control the speed of gas turbines or diesel generators to ensure stable power output.

Ship and offshore engineering:

Adjust the speed of ship engines to achieve dynamic positioning and navigation control.

Industrial manufacturing:

Applied to compressors,pumps and other equipment to optimize process efficiency.

Oil and gas:

Control the speed of drilling equipment to ensure operational stability.

4.Technical advantages

High-precision control:

Using PID algorithm and differential gain adjustment technology,the overshoot is low and the response speed is fast,with a control accuracy of±0.5%.

Flexible expansion:

Can be used with Woodward 2301,500 series or NetCon controllers to support distributed control system architecture.

Reliability design:

ISO 9001 certified,mean time between failures(MTBF)exceeds 50,000 hours,and is suitable for high temperature and high vibration industrial environments.