描述

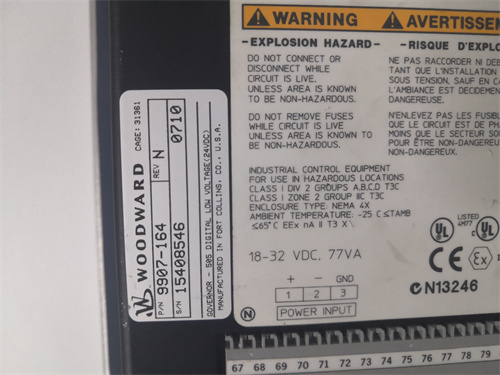

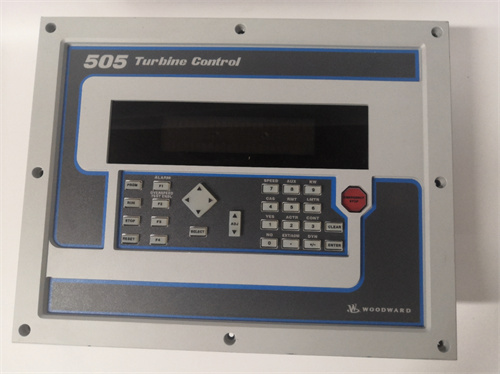

Woodward 9907-164数字微处理器控制器模块是伍德沃德(Woodward)公司针对工业涡轮机控制设计的核心设备,属于其经典505/505E系列调速器控制单元的一部分。以下是其综合技术特性与应用概述:

1.产品概述

核心定位:基于微处理器的数字控制器,专为蒸汽涡轮机、燃气涡轮机、水轮机及工业膨胀机设计,用于精确控制转速、负荷及启动/停机流程。

功能覆盖:支持转速控制、功率调节、同步控制(等时模式)、阀门驱动及安全保护,适用于发电、石油化工、冶金等工业场景。

2.核心功能

(1)控制与调节能力

转速与负荷控制:通过分程执行器驱动蒸汽进口阀,实现汽轮机转速与负荷的精确调节,支持蒸汽、燃气及水轮机的启动、停止与并网控制。

同步控制:等时模式下可实现多台机组功率分配与频率同步,保障电网稳定性。

(2)数据采集与监测

实时参数监控:采集转速、温度、压力、功率等关键数据,通过两行24字符显示屏或远程HMI(如OpView、505View)显示运行状态。

数据记录与分析:支持历史趋势分析与故障诊断,优化设备维护策略。

(3)安全与保护机制

临界速度规避:自动避免涡轮机进入共振区域,防止结构损伤。

阀门限制器:限制执行器开度,保护设备免受过载冲击。

紧急停机保护:启动时预设停机先出指示器,防止超速或失控导致人身伤害。

3.技术规格

输入/输出接口:

离散输入:16个触点输入(4专用+12可编程)。

模拟输入:6个4-20mA可编程电流输入。

输出信号:0-10V DC模拟量输出,驱动执行器或阀门。

通信协议:支持RS-232、Ethernet(Modbus)、CANbus等,实现与DCS/PLC系统联动。

物理参数:

尺寸:约15.2×5.1×20.3 cm。

重量:约0.7 kg。

工作温度:-10℃至60℃(或-4°F至+140°F)。

防护等级:IP56(IEC 60529),抗振动与高湿环境。

4.应用场景

发电领域:火力发电、燃气轮机并网控制,保障电网频率稳定。

石油化工:压缩机、泵等设备转速调节,维持生产流程连续性。

冶金行业:轧机、风机负荷控制,优化能源效率。

船舶与海洋:推进系统稳定运行,提升海上平台备用电源可靠性。

Woodward 9907-164 digital microprocessor controller module is a core device designed by Woodward for industrial turbine control and is part of its classic 505/505E series governor control unit.The following is an overview of its comprehensive technical features and applications:

1.Product Overview

Core positioning:A microprocessor-based digital controller designed for steam turbines,gas turbines,water turbines and industrial expanders for precise control of speed,load and start/stop processes.

Function coverage:Supports speed control,power regulation,synchronous control(isochronous mode),valve drive and safety protection,suitable for industrial scenarios such as power generation,petrochemicals,and metallurgy.

2.Core functions

(1)Control and regulation capabilities

Speedand load control:The steam inlet valve is driven by a split-range actuator to achieve precise regulation of turbine speed and load,and supports the start,stop and grid connection control of steam,gas and water turbines.

Synchronous control:In isochronous mode,power distribution and frequency synchronization of multiple units can be achieved to ensure grid stability.

(2)Data collection and monitoring

Real-time parameter monitoring:collect key data such as speed,temperature,pressure,power,etc.,and display the operating status through a two-line 24-character display or remote HMI(such as OpView,505View).

Data recording and analysis:support historical trend analysis and fault diagnosis,and optimize equipment maintenance strategy.

(3)Safety and protection mechanism

Critical speed avoidance:automatically avoid the turbine from entering the resonance area to prevent structural damage.

Valve limiter:limit the actuator opening to protect the equipment from overload shock.

Emergency shutdown protection:preset shutdown first-out indicator at startup to prevent personal injury caused by overspeed or loss of control.

3.Technical specifications

Input/output interface:

Discrete input:16 contact inputs(4 dedicated+12 programmable).

Analog input:6 4-20mA programmable current inputs.

Output signal:0-10V DC analog output,drive actuator or valve.

Communication protocol:Supports RS-232,Ethernet(Modbus),CANbus,etc.,to achieve linkage with DCS/PLC system.

Physical parameters:

Dimensions:about 15.2×5.1×20.3 cm.

Weight:about 0.7 kg.

Operating temperature:-10℃to 60℃(or-4°F to+140°F).

Protection level:IP56(IEC 60529),anti-vibration and high humidity environment.

4.Application scenarios

Power generation:thermal power generation,gas turbine grid connection control,to ensure the stability of grid frequency.

Petrochemical:speed regulation of compressors,pumps and other equipment to maintain the continuity of production processes.

Metallurgical industry:rolling mill,fan load control,optimize energy efficiency.

Ship and ocean:stable operation of propulsion system,improve the reliability of backup power supply for offshore platforms.