描述

主要产品详情及功能

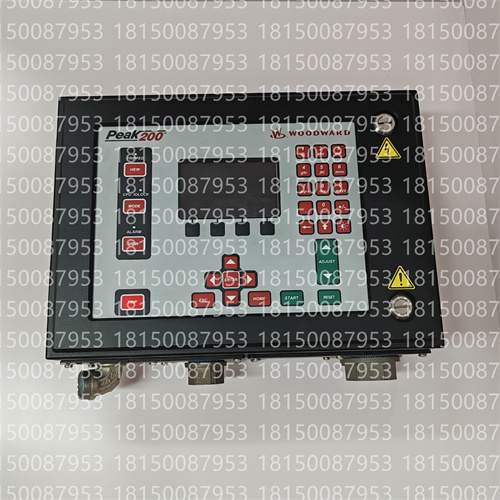

数字控制系统:Peak 200-HVAC是一款先进的数字控制器,采用先进的算法来管理和优化HVAC系统。与传统的模拟或纯机械控制器不同,它提供了更高的精度、灵活性和诊断能力。

HVAC特定应用:名称中的“HVAC”明确指明了其应用领域。它旨在控制大型工业或商用HVAC系统中的组件,例如:

离心式冷水机组:通常用于管理大型建筑或工业过程中的冷水机组中离心式压缩机的复杂启动、停机和负载控制。

冷却塔:控制风扇、泵和水流,实现高效散热。

空气处理机组(AHU):管理风扇转速、风门位置和温度/湿度水平。

锅炉:控制燃烧、蒸汽压力和水位。

精确控制:它可对关键HVAC参数进行高精度控制。这种精度有助于:

能源效率:优化系统运行以降低能耗。

稳定运行:精确维持设定值,防止温度/湿度波动。

延长设备寿命:通过优化运行和防止低效循环来减少磨损。

输入/输出(I/O)功能:作为控制系统,它具有各种传感器输入(温度、压力、流量)和控制执行器的输出(阀门、风门、电机变频器、风机/泵继电器)。I/O的具体数量和类型将在其技术规格中详细说明。

通信协议:像Peak 200-HVAC这样的现代工业控制器通常支持标准工业通信协议,以便集成到楼宇管理系统(BMS)或更高级别的SCADA/DCS系统中。常用协议包括Modbus(RTU或TCP/IP)或BACnet。

可编程性/可配置性:它是一个可编程单元,允许工程师通过专用软件工具配置控制策略、报警设定值和运行参数。这种定制对于适应不同的HVAC系统设计和运行要求至关重要。

可靠性:伍德沃德产品以其在严苛工业环境中的坚固性和可靠性而闻名。Peak 200-HVAC专为持续运行而设计,并具有抗电气噪声、温度波动和振动的能力。

诊断和报警:提供广泛的诊断功能,以监控系统健康状况并查明潜在问题。它可以针对超出规格的情况发出警报,从而帮助进行主动维护和故障排除。

通用规格(同类控制器通用)

8200-1501型号的具体详细规格可在伍德沃德的官方数据表或手册中找到,但通常包括:

输入电源:通常为24 VDC(或18-32 VDC等范围)。

工作温度:专为工业环境设计(例如0°C至70°C)。

安装方式:通常为DIN导轨安装或面板安装。

认证:可能包括CE、UL和其他相关工业认证。

软件:伍德沃德提供的配置和监控软件(例如,使用专有工具或标准接口)。

Key Product Details and Functions

Digital Control System:The Peak 200-HVAC is a sophisticated digital controller that uses advanced algorithms to manage and optimize HVAC systems.Unlike older analog or purely mechanical controls,it provides much greater precision,flexibility,and diagnostic capabilities.

HVAC Specific Application:The”HVAC”in its name specifically denotes its application.It’s designed to control components found in large industrial or commercial HVAC systems,such as:

Centrifugal Chillers:Often used to manage the complex startup,shutdown,and load control of centrifugal compressors in chillers for large buildings or industrial processes.

Cooling Towers:Control of fans,pumps,and water flow for efficient heat rejection.

Air Handling Units(AHUs):Managing fan speed,damper positions,and temperature/humidity levels.

Boilers:Control of combustion,steam pressure,and water levels.

Precise Control:It offers highly accurate control of critical HVAC parameters.This precision helps in:

Energy Efficiency:Optimizing system operation to reduce energy consumption.

Stable Operation:Maintaining setpoints accurately,preventing temperature/humidity swings.

Extended Equipment Life:Reducing wear and tear by optimizing operation and preventing inefficient cycling.

Input/Output(I/O)Capability:As a control system,it features various inputs for sensors(temperature,pressure,flow)and outputs for controlling actuators(valves,dampers,variable speed drives for motors,relays for fans/pumps).The specific number and type of I/O would be detailed in its technical specifications.

Communication Protocols:Modern industrial controllers like the Peak 200-HVAC typically support standard industrial communication protocols for integration into Building Management Systems(BMS)or higher-level SCADA/DCS systems.Common protocols include Modbus(RTU or TCP/IP)or BACnet.

Programmability/Configurability:It’s a programmable unit,allowing engineers to configure control strategies,alarm setpoints,and operational parameters via dedicated software tools.This customization is essential for adapting to different HVAC system designs and operational requirements.

Reliability:Woodward products are known for their robustness and reliability in demanding industrial environments.The Peak 200-HVAC is designed for continuous operation and resilience against electrical noise,temperature fluctuations,and vibrations.

Diagnostics and Alarming:Provides extensive diagnostic capabilities to monitor system health and pinpoint potential issues.It can generate alarms for out-of-spec conditions,aiding in proactive maintenance and troubleshooting.

General Specifications(Common for similar controllers)

Specific detailed specifications for the 8200-1501 model would be found in Woodward’s official datasheets or manuals,but generally,it would include:

Input Power:Typically 24 VDC(or a range like 18-32 VDC).

Operating Temperature:Designed for industrial environments(e.g.,0°C to 70°C).

Mounting:Often DIN-rail mountable or panel mount.

Certifications:Likely includes CE,UL,and other relevant industrial certifications.

Software:Configuration and monitoring software provided by Woodward(e.g.,using a proprietary tool or a standard interface).

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101