描述

WOODWARD 9907-167是伍德沃德(Woodward)公司开发的数字调速器控制模块,属于505E系列的核心组件之一,专为工业汽轮机、船舶动力系统及复杂旋转设备设计。以下是其详细产品简介:

一、产品概述

定位:基于32位微处理器的数字控制器,适用于蒸汽涡轮机、燃气轮机、水轮机等设备的转速、负荷及启动/停机流程管理。

功能:通过驱动进汽阀或抽汽阀实现汽轮机的精确控制,支持单抽汽/进汽模式,并兼容超速保护、负载限制等功能。

二、核心功能

调速与控制模式

-高精度控制:采用PID算法,转速控制精度±0.25%,响应时间<14 ms,适应复杂工况需求。

-多模式切换:支持等时控制、Droop控制、负荷共享及ISOchronous控制,满足不同应用场景需求。

-启动/停机管理:预设自动启动序列,支持临界转速规避与紧急停机保护。

数据采集与监测

-实时监控:通过LCD显示屏或HMI软件(OpView™/505View)展示转速、负荷、温度等参数,支持历史数据记录与趋势分析。

-报警与诊断:提供超速、过载、阀门卡滞等故障先出指示,并生成事件日志。

通信与扩展性

-协议兼容:支持RS-485、Modbus、Ethernet等接口,可与DCS/PLC、SCADA系统无缝集成。

-编程与配置:通过PC端工具实现参数设置与控制逻辑定制,支持现场组态与远程维护。

三、技术特点

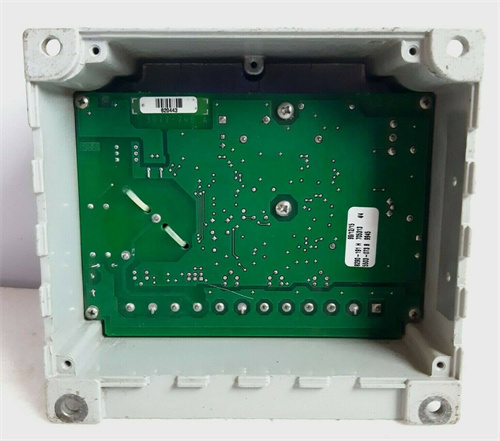

高可靠性:宽温设计(-40°C至+85°C),IP67防护等级,抗电磁干扰(EMC符合工业标准),适用于恶劣工业环境。

耐用性:采用加固型金属外壳,抗震、抗冲击,支持NEMA 4X级防护(选配)。

灵活性:支持多种电源输入(24 VDC/120 VAC),可扩展至多执行器控制,适应不同设备需求。

四、参数规格

输入/输出接口

-模拟输入:4-20 mA电流信号或1-5 V电压信号(可编程)。

-离散输入:16个触点输入(支持冗余配置)。

-输出:0-10 V DC模拟量输出或继电器输出。

物理参数

-尺寸:19英寸标准机架安装,深度<20 cm。

-重量:约1.5 kg(带防护外壳)。

功率与能耗

-输入电压:24 VDC(典型),支持宽压范围(18-32 VDC)。

-功耗:<15 W。

五、应用领域

发电与能源:火力发电厂、热电联产系统、分布式能源的汽轮机控制。

工业制造:化工、冶金、造纸行业的旋转机械(如压缩机、泵)调速。

船舶动力:海上平台、商船的主机转速与负载管理。

市政工程:区域供热系统、污水处理设施的涡轮机驱动设备。

WOODWARD 9907-167 is a digital governor control module developed by Woodward.It is one of the core components of the 505E series and is designed for industrial steam turbines,ship power systems and complex rotating equipment.The following is a detailed product introduction:

I.Product Overview

Positioning:A digital controller based on a 32-bit microprocessor,suitable for speed,load and start/shutdown process management of steam turbines,gas turbines,water turbines and other equipment.

Function:Accurately control the steam turbine by driving the steam inlet valve or extraction valve,support single extraction/inlet mode,and compatible with overspeed protection,load limit and other functions.

II.Core Function

SpeedRegulation and Control Mode

-High-precision control:Using PID algorithm,speed control accuracy of±0.25%,response time<14 ms,adapt to complex working conditions.

-Multi-mode switching:Supports isochronous control,Droop control,load sharing and ISOchronous control to meet the needs of different application scenarios.

-Start/Stop Management:Preset automatic start sequence,support critical speed avoidance and emergency shutdown protection.

Data Acquisition and Monitoring

-Real-time Monitoring:Display speed,load,temperature and other parameters through LCD display or HMI software(OpView™/505View),support historical data recording and trend analysis.

-Alarm and Diagnosis:Provides first-come-first-served indication of overspeed,overload,valve jamming and other faults,and generates event logs.

Communication and Scalability

-Protocol Compatibility:Supports RS-485,Modbus,Ethernet and other interfaces,and can be seamlessly integrated with DCS/PLC and SCADA systems.

-Programming and Configuration:Parameter setting and control logic customization are realized through PC-side tools,supporting on-site configuration and remote maintenance.

III.Technical Features

High reliability:wide temperature design(-40°C to+85°C),IP67 protection level,anti-electromagnetic interference(EMC meets industrial standards),suitable for harsh industrial environments.

Durability:Reinforced metal housing,shock and vibration resistant,supports NEMA 4X protection(optional).

Flexibility:Supports multiple power inputs(24 VDC/120 VAC),can be expanded to multiple actuator controls,and adapts to different equipment requirements.

IV.Specifications

Input/output interface

-Analog input:4-20 mA current signal or 1-5 V voltage signal(programmable).

-Discrete input:16 contact inputs(supports redundant configuration).

-Output:0-10 V DC analog output or relay output.

Physical parameters

-Dimensions:19-inch standard rack installation,depth<20 cm.

-Weight:about 1.5 kg(with protective housing).

Power and energy consumption

-Input voltage:24 VDC(typical),supports a wide voltage range(18-32 VDC).

-Power consumption:<15 W.

5.Application fields

Power generation and energy:turbine control of thermal power plants,cogeneration systems,and distributed energy.

Industrial manufacturing:speed regulation of rotating machinery(such as compressors and pumps)in the chemical,metallurgical,and papermaking industries.

Ship power:main engine speed and load management of offshore platforms and merchant ships.

Municipal engineering:turbine drive equipment for regional heating systems and sewage treatment facilities.