描述

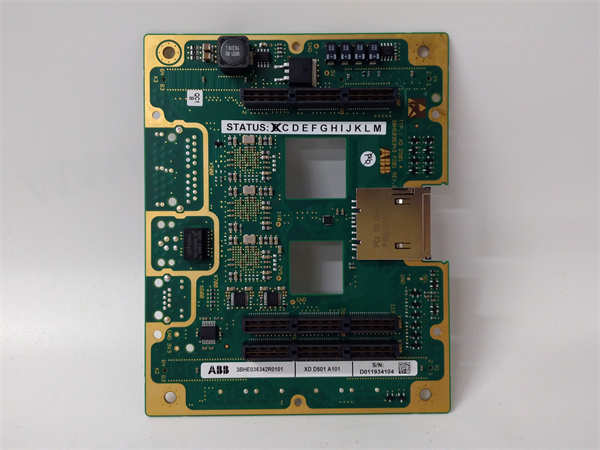

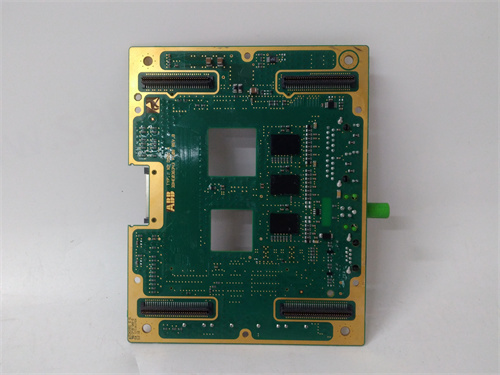

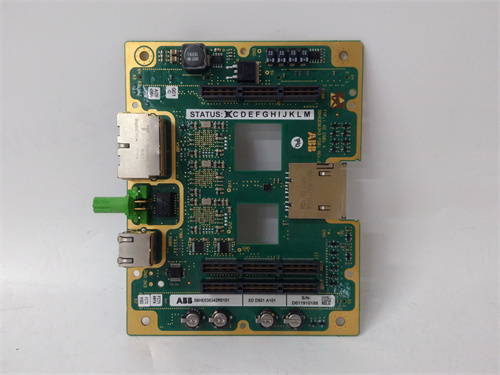

XDD501A101 3BHE036342R0101产品详情

一、产品概述

XDD501A101 3BHE036342R0101是ABB公司生产的一款总线终端模块,属于Advant Controller 31系列,主要用于工业自动化系统中控制各种过程和设备。该模块具备高可靠性和灵活性,能够满足工业控制领域对精确控制和数据通信的需求。

二、核心功能

总线通信功能:作为总线终端模块,该设备连接到工业总线系统,充当总线上的终端设备,支持数据交换和通信。它可能支持常见的工业总线协议,如PROFIBUS、Modbus、Ethernet/IP等,实现设备间的高效数据传输。

多通道输入输出:模块配备多种数字输入、输出和模拟输入接口,用于与外部设备进行交互,满足不同工业场景下的控制需求。

实时控制与监控:支持实时数据采集、处理和控制信号传输,能够快速响应工业过程中的变化,实现实时监控和控制。

系统集成能力:模块化设计便于与其他设备和系统集成,支持与PLC、DCS等控制设备通信,实现更高级别的系统集成和协同工作。

三、技术规格

工作电压:24VDC,输入电压范围为20VDC至28VDC,适应工业环境中的电压波动。

通信接口:配备RS-232通信接口,支持与其他设备进行串行通信。

环境适应性:

工作温度范围:0℃至50℃,能够在较宽的温度范围内稳定运行。

存储温度范围:-40℃至85℃,适应极端存储环境。

相对湿度:0%至95%(无凝露),适用于高湿度环境。

防护等级:IP67,具备一定的防尘和防水能力,适合在恶劣的工业环境中使用。

外形尺寸与重量:外形尺寸为100mm×80mm×30mm,重量为0.2kg,结构紧凑,便于安装和维护。

四、产品优势

高可靠性:采用优质材料和先进技术,确保在恶劣工业环境下长期稳定运行,减少停机时间。

灵活配置:模块化设计支持参数自定义设置,适配不同应用需求,易于扩展和升级。

易维护性:具备故障自诊断功能,可快速定位问题并提示维护,支持热插拔,降低维护成本。

高精度控制:能够精确控制励磁电流等参数,适用于需要高精度控制的工业自动化应用。

五、应用领域

工业自动化:用于工业生产线、制造过程等需要自动化控制的应用,实现设备的精确控制和高效运行。

能源管理:在电力和能源领域,用于电网控制、发电设备控制等,提高能源利用效率。

楼宇自动化:控制照明、暖通空调、安全系统等,实现能源节约和舒适性提升。

交通运输:用于交通信号控制、轨道交通系统等,提高运输设施的管理效率。

XDD501A101 3BHE036342R0101 Product Details

1.Product Overview

XDD501A101 3BHE036342R0101 is a bus terminal module produced by ABB,belonging to the Advant Controller 31 series,mainly used to control various processes and equipment in industrial automation systems.The module has high reliability and flexibility,and can meet the needs of precise control and data communication in the field of industrial control.

2.Core Functions

Bus communication function:As a bus terminal module,the device is connected to the industrial bus system,acts as a terminal device on the bus,and supports data exchange and communication.It may support common industrial bus protocols such as PROFIBUS,Modbus,Ethernet/IP,etc.,to achieve efficient data transmission between devices.

Multi-channel input and output:The module is equipped with a variety of digital input,output and analog input interfaces for interaction with external devices to meet the control needs in different industrial scenarios.

Real-time control and monitoring:Supports real-time data acquisition,processing and control signal transmission,can quickly respond to changes in industrial processes,and achieve real-time monitoring and control.

System integration capability:The modular design facilitates integration with other devices and systems,supports communication with control devices such as PLC and DCS,and achieves higher levels of system integration and collaborative work.

III.Technical specifications

Operating voltage:24VDC,input voltage range is 20VDC to 28VDC,adapting to voltage fluctuations in industrial environments.

Communication interface:Equipped with RS-232 communication interface,supporting serial communication with other devices.

Environmental adaptability:

Operating temperature range:0℃to 50℃,able to operate stably in a wide temperature range.

Storage temperature range:-40℃to 85℃,adapting to extreme storage environments.

Relative humidity:0%to 95%(no condensation),suitable for high humidity environments.

Protection level:IP67,with certain dust and water resistance,suitable for use in harsh industrial environments.

Dimensions and weight:The dimensions are 100mm×80mm×30mm,the weight is 0.2kg,the structure is compact,and it is easy to install and maintain.

4.Product Advantages

High reliability:high-quality materials and advanced technology are used to ensure long-term stable operation in harsh industrial environments and reduce downtime.

Flexible configuration:modular design supports custom parameter settings,adapts to different application requirements,and is easy to expand and upgrade.

Easy to maintain:with fault self-diagnosis function,it can quickly locate problems and prompt maintenance,support hot plugging,and reduce maintenance costs.

High-precision control:It can accurately control parameters such as excitation current,and is suitable for industrial automation applications that require high-precision control.

5.Application fields

Industrial automation:used in industrial production lines,manufacturing processes and other applications that require automated control to achieve precise control and efficient operation of equipment.

Energy management:in the field of electricity and energy,it is used for power grid control,power generation equipment control,etc.to improve energy utilization efficiency.

Building automation:control lighting,HVAC,security systems,etc.to achieve energy savings and comfort improvement.

Transportation:used for traffic signal control,rail transit systems,etc.to improve the management efficiency of transportation facilities.