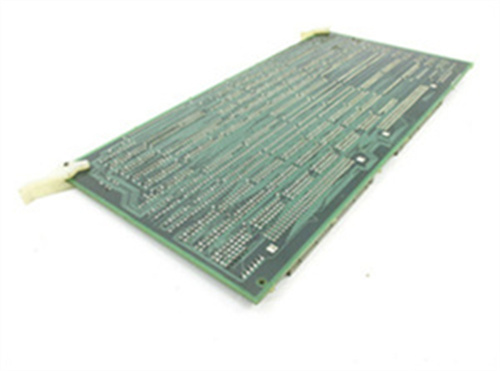

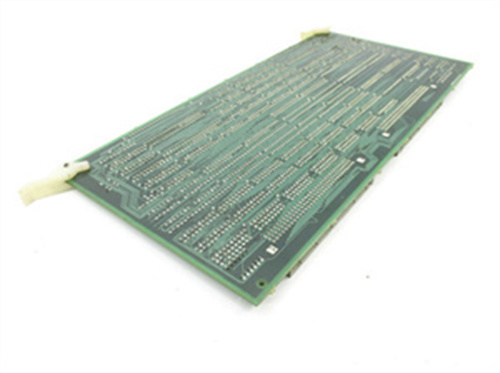

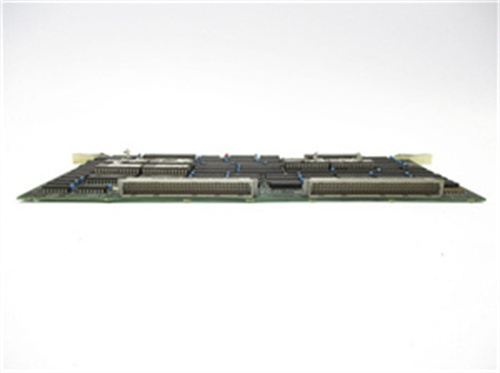

描述

YASKAWA CACR-SR07BE12M控制模块技术说明

核心功能

伺服电机精准控制

多轴协同运动:支持同时控制多个伺服电机,协调复杂运动轨迹,适用于机器人、自动化产线等场景。

高精度定位:通过编码器反馈实时监测电机位置,闭环控制精度达微米级,确保定位稳定性。

动态参数调节:支持速度、加速度、力矩的独立控制,适应不同负载需求,如高速切割或精密装配。

多功能信号处理

多通道数字输入:集成12路数字量输入通道,兼容开关量、脉冲计数等信号,支持逻辑编程与状态监测。

传感器集成:内置温度、压力、流量等传感器接口,可扩展振动监测功能,实现设备状态实时反馈。

工业级通信能力

多协议兼容:支持Modbus、CANopen、EtherCAT等工业协议,适配PLC、SCADA系统及上位机软件。

远程监控:通过以太网或串口实现参数配置、故障诊断及运行状态远程访问,提升运维效率。

技术参数

处理器性能:

高速数字信号处理器(DSP),运算频率≥100MHz,支持实时控制算法。

接口配置:

数字输入:12路隔离通道(兼容NPN/PNP信号)。

通信接口:

以太网(100Mbps)

RS-485/RS-232串口

-EtherCAT主站接口(可选)

传感器接口:4-20mA模拟输入、DI/DO扩展接口。

环境适应性:

工作温度:-10°C至50°C(宽温设计)。

防护等级:IP65(防尘防水),抗振动/冲击(符合IEC 60068标准)。

设计亮点

高可靠性与抗干扰

电磁兼容性:通过CE、UL认证,支持工业环境强电磁干扰下的稳定运行。

冗余设计:关键模块支持热插拔,故障时自动切换备用通道,保障系统连续性。

灵活可编程性

图形化编程:支持梯形图(LD)、结构化文本(ST)等IEC 61131-3标准语言。

参数自定义:可配置脉冲频率(最高1MHz)、加速度曲线及运动模式,适配定制化需求。

实时反馈与诊断

状态监测:实时显示电机温度、电流、位置偏差等数据,支持故障代码解析与报警触发。

数据记录:内置存储器可记录运行日志,便于分析设备性能与优化控制策略。

YASKAWA CACR-SR07BE12M Control Module Technical Description

Core functions

Precise control of servo motors

Multi-axis collaborative motion:supports the control of multiple servo motors at the same time,coordinates complex motion trajectories,and is suitable for robots,automated production lines and other scenarios.

High-precision positioning:Real-time monitoring of motor position through encoder feedback,the closed-loop control accuracy reaches micron level,ensuring positioning stability.

Dynamic parameter adjustment:supports independent control of speed,acceleration and torque,and adapts to different load needs,such as high-speed cutting or precision assembly.

Multifunctional signal processing

Multi-channel digital input:Integrated 12 digital input channels,compatible with switch quantity,pulse counting and other signals,and supports logic programming and status monitoring.

Sensor integration:built-in sensor interfaces such as temperature,pressure,and flow,which can expand vibration monitoring functions and realize real-time feedback on the device status.

Industrial communication capabilities

Multi-protocol compatibility:supports industrial protocols such as Modbus,CANopen,EtherCAT,etc.,and is adapted to PLC,SCADA system and host computer software.

Remote monitoring:Use Ethernet or serial port to realize parameter configuration,fault diagnosis and remote access to operating status to improve operation and maintenance efficiency.

Technical parameters

Processor performance:

High-speed digital signal processor(DSP),operation frequency≥100MHz,supports real-time control algorithms.

Interface configuration:

Digital input:12 isolated channels(compatible with NPN/PNP signals).

Communication interface:

Ethernet(100Mbps)

RS-485/RS-232 serial port

-EtherCAT master interface(optional)

Sensor interface:4-20mA analog input,DI/DO expansion interface.

Environmental adaptability:

Operating temperature:-10°C to 50°C(wide temperature design).

Protection level:IP65(dust-proof and waterproof),vibration/impact resistance(compliant with IEC 60068 standard).

Design Highlights

High reliability and anti-interference

Electromagnetic compatibility:Passed CE and UL certification,and supports stable operation under strong electromagnetic interference in the industrial environment.

Redundant design:The key module supports hot swapping,and automatically switches the backup channel in case of failure to ensure system continuity.

Flexible programmability

Graphical programming:Supports IEC 61131-3 standard languagessuch as ladder diagrams(LD),structured text(ST).

Parameter customization:It can be configured with pulse frequency(up to 1MHz),acceleration curve and motion mode to adapt to customized requirements.

Real-time feedback and diagnosis

Status monitoring:Displays motor temperature,current,position deviation and other data in real time,and supports fault code analysis and alarm triggering.

Data logging:Built-in memory can record operation logs,which facilitates analysis of device performance and optimization control strategies.