描述

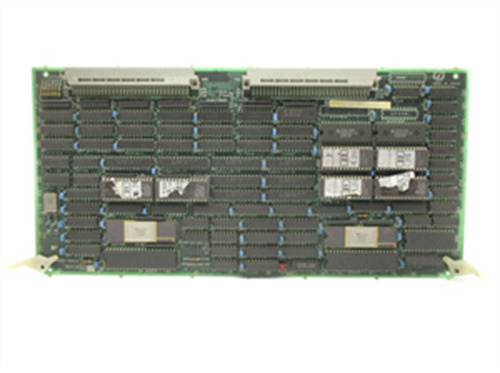

YASKAWA CP-317/217IF是一款模块化可编程逻辑控制器(PLC),专为工业自动化系统设计,具备高扩展性、可靠性和灵活性。以下是其核心功能与技术特点的综合解析:

一、产品类型与结构

模块化设计:采用模块化架构,支持CPU、电源、I/O接口及功能模块的灵活扩展,适用于大中型控制系统需求。

PLC核心功能:集逻辑控制、数据采集、通信协议解析于一体,支持梯形图、功能块图等编程语言,兼容主流工业协议(如PROFINET、EtherNet/IP)。

二、技术参数与性能

电源与功耗

输入电压:24V DC(部分型号支持110/220V AC)

功耗:典型值<50 W(取决于扩展模块数量)

I/O能力

标准配置:数字量I/O点数≥256,模拟量I/O通道≥32(支持±10V、4-20mA信号)

扩展支持:通过通信总线最多可扩展至2048个I/O点。

防护与环境适应性

防护等级:IP20

工作温度:-20°C至+70°C(存储温度-40°C至+85°C)

抗干扰能力:符合EMC工业级标准。

三、核心功能与优势

高可靠性

冗余电源与通信模块设计,支持热插拔维护,降低停机风险。

内置故障诊断与日志记录功能,便于快速定位异常。

智能通信

支持以太网、RS-422/485等接口,可无缝集成至SCADA、DCS或云平台。

兼容OPC UA协议,支持加密与远程监控。

扩展性

支持运动控制模块、温度调节模块等扩展,满足复杂应用场景需求。

兼容第三方设备(如变频器、传感器),降低系统集成成本。

四、典型应用场景

工业自动化

自动化生产线控制、机器人协同作业、智能仓储系统。

电力与能源

发电站设备监控、变电站电压调节、新能源并网控制。

交通与物流

轨道交通信号控制、停车场管理系统、港口装卸设备。

制造业

汽车制造、纺织机械、化工流程控制等。

YASKAWA CP-317/217IF is a modular programmable logic controller(PLC)designed for industrial automation systems with high scalability,reliability and flexibility.The following is a comprehensive analysis of its core functions and technical features:

1.Product type and structure

Modular design:It adopts a modular architecture to support flexible expansion of CPU,power supply,I/O interface and functional modules,suitable for large and medium-sized control system requirements.

PLC core functions:It integrates logic control,data acquisition,and communication protocol analysis,supports programming languagessuch as ladder diagrams and function block diagrams,and is compatible with mainstream industrial protocols(such as PROFINET and EtherNet/IP).

2.Technical parameters and performance

Power supply and power consumption

Input voltage:24V DC(some models support 110/220V AC)

Power consumption:typical value<50 W(depending on the number of expansion modules)

I/O capability

Standard configuration:digital I/O points≥256,analog I/O channels≥32(support±10V,4-20mA signals)

Expansion support:can be expanded to up to 2048 I/O points through the communication bus.

Protection and environmental adaptability

Protection level:IP20

Operating temperature:-20°C to+70°C(storage temperature-40°C to+85°C)

Anti-interference ability:meets EMC industrial standards.

3.Core functions and advantages

High reliability

Redundant power supply and communication module design,support hot-swap maintenance,reduce downtime risk.

Built-in fault diagnosis and logging functions,easy to quickly locate abnormalities.

Intelligent communication

Supports Ethernet,RS-422/485 and other interfaces,and can be seamlessly integrated into SCADA,DCS or cloud platforms.

Compatible with OPC UA protocol,supports encryption and remote monitoring.

Scalability

Supports expansions such as motion control modules and temperature control modules to meet the needs of complex application scenarios.

Compatible with third-party devices(such as inverters,sensors)to reduce system integration costs.

IV.Typical application scenarios

Industrial automation

Automated production line control,robot collaborative operation,intelligent warehousing system.

Power and energy

Power station equipment monitoring,substation voltage regulation,new energy grid connection control.

Transportation and logistics

Railway traffic signal control,parking lot management system,port loading and unloading equipment.

Manufacturing

Automobile manufacturing,textile machinery,chemical process control,etc.