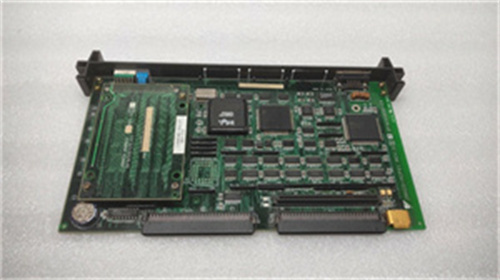

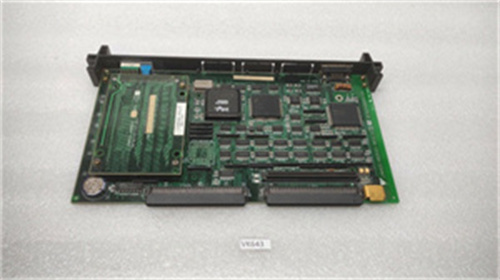

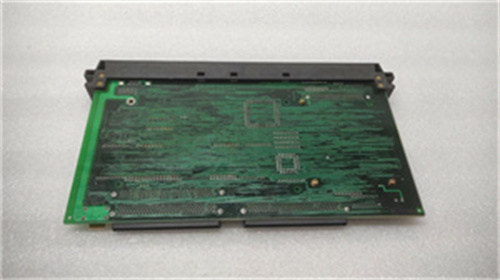

描述

YASKAWA DF92006500-C0是安川电机(YASKAWA)为工业自动化系统设计的高性能逻辑控制模块,属于PLC/DCS系统核心组件,适用于能源、制造、化工及电力等复杂工业场景。以下是其综合技术特性与应用场景分析:

1.核心功能

多语言编程支持:

支持梯形图(LAD)、功能块(FBD)、结构化文本(ST)及顺序功能图(SFC)编程,兼容主流工业自动化软件工具,满足不同开发习惯需求。

高速通信能力:

集成EtherCAT、Profinet、Modbus TCP等工业协议,支持与西门子、三菱等控制系统无缝对接,实现数据交互与协同控制。

运动控制扩展:

可与安川伺服驱动器(如J1系列)级联,提供多轴同步控制功能,适用于机器人、数控机床等高精度运动场景。

2.技术参数

处理性能:

主频200MHz,最大程序容量2MB,支持多任务并行处理,适合复杂算法(如自适应PID、模糊控制)及大数据量处理。

I/O扩展:

标准配置64点数字量输入/输出(DI/DO),支持模拟量扩展模块(AI/AO),最大扩展至512点,兼容24V DC/AC信号。

防护等级:

工作温度范围-40℃至70℃,防护等级IP20,符合EN 61000电磁兼容标准,支持长期工业环境运行。

3.应用场景

能源与电力:

用于风电变流器控制、变电站自动化,实现电网同步、功率分配及故障保护。

智能制造:

驱动工业机器人、3D打印机的运动控制器,支持多轴协同与工艺参数优化。

化工与制药:

管理反应釜温度、压力等关键参数,实现闭环控制与安全生产。

轨道交通:

控制列车牵引系统逻辑,支持紧急制动与冗余切换。

YASKAWA DF92006500-C0 is a high-performance logic control module designed by Yaskawa Electric(YASKAWA)for industrial automation systems.It is a core component of the PLC/DCS system and is suitable for complex industrial scenarios such as energy,manufacturing,chemical industry and power.The following is an analysis of its comprehensive technical characteristics and application scenarios:

1.Core functions

Multi-language programming support:

Supports ladder diagram(LAD),function block(FBD),structured text(ST)and sequential function chart(SFC)programming,compatible with mainstream industrial automation software tools,and meets the needs of different development habits.

High-speed communication capability:

Integrates industrial protocols such as EtherCAT,Profinet,Modbus TCP,etc.,supports seamless docking with control systems such as Siemens and Mitsubishi,and realizes data interaction and collaborative control.

Motion control expansion:

Can be cascaded with Yaskawa servo drives(such as J1 series),providing multi-axis synchronous control functions,suitable for high-precision motion scenarios such as robots and CNC machine tools.

2.Technical parameters

Processing performance:

Main frequency 200MHz,maximum program capacity 2MB,supports multi-task parallel processing,suitable for complex algorithms(such as adaptive PID,fuzzy control)and large data processing.

I/O expansion:

Standard configuration 64-point digital input/output(DI/DO),support analog expansion module(AI/AO),maximum expansion to 512 points,compatible with 24V DC/AC signal.

Protection level:

Operating temperature range-40℃to 70℃,protection level IP20,in line with EN 61000 electromagnetic compatibility standard,support long-term industrial environment operation.

3.Application scenarios

Energy and power:

Used for wind power converter control,substation automation,grid synchronization,power distribution and fault protection.

Intelligent manufacturing:

Motion controller that drives industrial robots and 3D printers,supports multi-axis collaboration and process parameter optimization.

Chemical and pharmaceutical:

Manage key parameters such as reactor temperature and pressure to achieve closed-loop control and safe production.

Rail transit:

Control the logic of train traction system and support emergency braking and redundant switching.