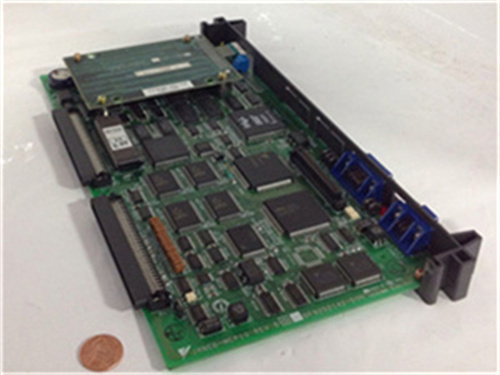

描述

Yaskawa DF9202142-DON是安川电机(Yaskawa)旗下的一款工业变频器,专为高精度速度控制与高效能源管理设计,适用于机械制造、冶金、化工及能源等工业领域。以下是其综合技术特性与应用分析:

1.核心功能

矢量控制技术:

采用无传感器矢量控制(SVC)或带编码器的闭环矢量控制(FVC),实现0.5Hz低转速高扭矩输出,适用于重载启动与精密定位场景。

多段速与工艺控制:

支持16段速设定及自学习功能,可编程逻辑控制(PLC)指令支持,满足复杂工艺流程需求。

网络兼容性:

集成Modbus RTU、Profinet、EtherCAT等通信协议,支持与主流PLC、SCADA系统无缝集成。

2.技术参数

额定功率与电压:

额定功率1.5kW,工作电压范围200-240V AC,适用于中小型电机驱动。

防护等级:

IP20标准防护,适应普通工业环境;可选配扩展模块提升防护性能。

控制精度:

速度控制精度±0.5%,转矩控制精度±1%,响应时间<20ms。

3.应用场景

机械制造:

驱动数控机床主轴、传送带等设备,实现高精度定位与动态负载补偿。

冶金与化工:

控制风机、泵类设备转速,优化能源利用率,降低能耗。

能源行业:

应用于光伏逆变器、风电变桨系统,提升发电效率与系统稳定性。

物流与电梯:

精确控制升降机、分拣机速度,保障运行平稳性。

4.技术优势

节能模式:

自动检测负载变化,动态调整输出功率,节能效率可达30%以上。

智能诊断:

内置故障自诊断功能,支持LED指示灯与远程通信故障代码上传,缩短维护时间。

扩展性:

支持扩展模块(如多段速扩展、安全模块等),灵活适配复杂系统需求。

Yaskawa DF9202142-DON is an industrial inverter under Yaskawa Electric,designed for high-precision speed control and efficient energy management,suitable for industrial fields such as machinery manufacturing,metallurgy,chemical industry and energy.The following is its comprehensive technical characteristics and application analysis:

1.Core functions

Vector control technology:

Adopt sensorless vector control(SVC)or closed-loop vector control(FVC)with encoder to achieve 0.5Hz low speed and high torque output,suitable for heavy load starting and precision positioning scenarios.

Multi-speed and process control:

Support 16-speed setting and self-learning function,programmable logic control(PLC)instruction support to meet the needs of complex process flow.

Network compatibility:

Integrated Modbus RTU,Profinet,EtherCAT and other communication protocols,support seamless integration with mainstream PLC and SCADA systems.

2.Technical parameters

Rated power and voltage:

Rated power 1.5kW,operating voltage range 200-240V AC,suitable for small and medium-sized motor drive.

Protection level:

IP20 standard protection,suitable for ordinary industrial environment;optional expansion modules can be used to improve protection performance.

Control accuracy:

Speedcontrol accuracy±0.5%,torque control accuracy±1%,response time<20ms.

3.Application scenarios

Mechanical manufacturing:

Drive CNC machine tool spindles,conveyor belts and other equipment to achieve high-precision positioning and dynamic load compensation.

Metallurgy and chemical industry:

Control the speed of fans and pumps,optimize energy utilization and reduce energy consumption.

Energy industry:

Applied to photovoltaic inverters and wind power variable pitch systems to improve power generation efficiency and system stability.

Logistics and elevators:

Precisely control the speed of elevators and sorting machines to ensure smooth operation.

4.Technical advantages

Energy saving mode:

Automatically detect load changes and dynamically adjust output power,with energy saving efficiency of more than 30%.

Intelligent diagnosis:

Built-in fault self-diagnosis function,supports LED indicator lights and remote communication fault code upload,shortening maintenance time.

Scalability:

Supports expansion modules(such as multi-speed expansion,safety modules,etc.),and flexibly adapts to complex system requirements.