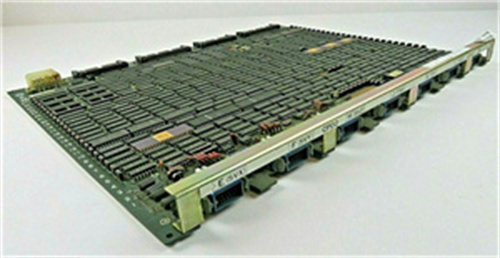

描述

YASKAWA JANCD-CP05C是安川电机(YASKAWA)Σ-Ⅴ系列的核心控制模块,专为工业自动化系统设计,广泛应用于能源、电力、机器人及智能制造等领域。以下是其综合技术特性与应用场景分析:

1.核心功能

高性能控制:

作为Σ-Ⅴ系列的扩展模块,JANCD-CP05C支持高速响应(整定时间<100ms)与振动抑制技术,优化伺服电机的跟随性能,尤其适用于高精度定位、高速加减速及复杂运动控制场景。

通信兼容性:

集成MECHATROLINK-II、Modbus等工业协议,支持与主流PLC(如西门子、施耐德)及机器人控制系统无缝对接,实现数据高效传输与协同控制。

扩展灵活性:

提供数字量输入/输出(DI/DO)接口,兼容模拟量信号扩展,支持与Σ-Ⅴ系列其他模块级联,满足分布式系统的复杂需求。

2.技术特点

调谐简便性:

配备新型自动调谐功能,整定时间缩短至约4ms(传统产品的1/10),支持单参数快速优化,降低调试复杂度。

工业级可靠性:

采用宽温设计(-40℃至70℃),抗电磁干扰能力符合IP20防护标准,平均无故障时间(MTBF)超50,000小时,适用于7×24小时连续运行环境。

振动抑制技术:

通过改进的算法减少驱动时的机械振动,提升设备稳定性与使用寿命,尤其在高负载或精密加工场景中表现突出。

3.应用场景

机器人系统:

驱动工业机器人本体的运动控制单元,实现多轴协同、高速分拣及精密装配,如三一重工智慧工厂中机器人系统的集成控制。

能源电力:

应用于智能变电站自动化、燃气轮机控制,优化电网同步与功率分配响应速度。

智能制造:

驱动数控机床伺服系统,实现高精度铣削、磨削等工序的实时调控。

轨道交通:

支持列车牵引系统的输出控制与冗余设计,确保紧急制动的快速响应。

YASKAWA JANCD-CP05C is the core control module of theΣ-V series of Yaskawa Electric(YASKAWA),designed for industrial automation systems and widely used in energy,electricity,robotics and intelligent manufacturing.The following is an analysis of its comprehensive technical characteristics and application scenarios:

1.Core functions

High-performance control:

As an expansion module of theΣ-V series,JANCD-CP05C supports high-speed response(setting time<100ms)and vibration suppression technology,optimizes the following performance of servo motors,and is especially suitable for high-precision positioning,high-speed acceleration and deceleration,and complex motion control scenarios.

Communication compatibility:

Integrated with industrial protocols such as MECHATROLINK-II and Modbus,supports seamless connection with mainstream PLCs(such as Siemens,Schneider)and robot control systems,and realizes efficient data transmission and collaborative control.

Expansion flexibility:

Provides digital input/output(DI/DO)interface,compatible with analog signal expansion,supports cascading with other modules of theΣ-V series,and meets the complex needs of distributed systems.

2.Technical features

Easy tuning:

Equipped with a new automatic tuning function,the setting time is shortened to about 4ms(1/10 of traditional products),supporting rapid optimization of single parameters and reducing debugging complexity.

Industrial-grade reliability:

Adopting a wide temperature design(-40℃to 70℃),the anti-electromagnetic interference capability meets the IP20 protection standard,and the mean time between failures(MTBF)exceeds 50,000 hours,suitable for 7×24 hours continuous operation environment.

Vibration suppression technology:

Through improved algorithms,mechanical vibration during driving is reduced,and the stability and service life of the equipment are improved,especially in high-load or precision processing scenarios.

3.Application scenarios

Robot system:

Drive the motion control unit of the industrial robot body to achieve multi-axis collaboration,high-speed sorting and precision assembly,such as the integrated control of the robot system in the smart factory of Sany Heavy Industry.

Energy and power:

Applied to intelligent substation automation and gas turbine control to optimize grid synchronization and power distribution response speed.

Intelligent manufacturing:

Drive the servo system of CNC machine tools to achieve real-time control of high-precision milling,grinding and other processes.

Railway transportation:

Supports output control and redundant design of train traction systems to ensure rapid response to emergency braking.