描述

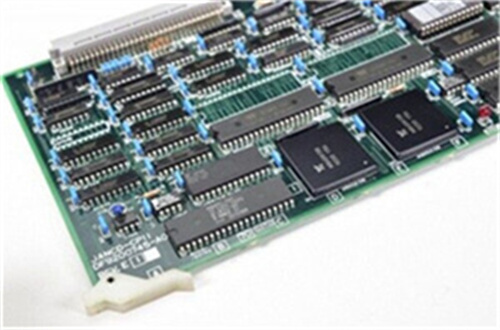

YASKAWA JANCD-CPII是安川电机(YASKAWA)为工业自动化系统设计的核心控制模块,属于PLC/DCS系统的核心组件,广泛应用于电力、汽车、钢铁及能源等领域。以下是其综合技术特性与应用场景分析:

1.核心功能

高可靠性控制:

作为PLC系统的核心模块,JANCD-CPII负责逻辑控制、数据采集与处理,支持复杂工业场景的实时响应与高精度执行,适用于7×24小时连续运行环境。

多协议兼容性:

支持Modbus、Profinet、EtherCAT等工业通信协议,可无缝对接西门子、施耐德等主流控制系统,实现数据交互与多设备协同控制。

扩展能力:

提供数字量/模拟量输入输出接口,支持与伺服驱动器、传感器及机器人系统级联,满足分布式系统扩展需求。

2.技术特点

工业级防护:

采用宽温设计(-40℃至70℃),抗电磁干扰能力符合IP20防护标准,平均无故障时间(MTBF)超50,000小时,适应严苛工业环境。

智能诊断与维护:

内置自检功能,支持故障代码实时显示与远程维护,缩短停机时间并降低维护成本。

灵活配置:

支持梯形图(LAD)、功能块(FBD)等编程语言,兼容主流组态软件(如西门子TIA Portal),降低开发门槛。

3.应用场景

电力行业:

应用于智能变电站自动化、发电机组控制,优化电网同步与功率分配响应速度。

汽车制造:

驱动焊接、喷涂等机器人工作站的逻辑控制单元,实现高精度定位与节拍优化。

钢铁工业:

管理炼钢炉温控、轧钢机同步等工艺流程,确保生产效率与安全性。

能源与化工:

支持燃气轮机控制、反应釜压力监控等场景,实现报警输出与异常处理。

4.技术优势

快速部署:

内置标准协议模板,可快速集成到现有自动化工程中,缩短实施周期。

模块化设计:

支持与安川伺服驱动器(如Σ-Ⅴ系列)及机器人系统无缝衔接,降低系统开发复杂度。

维护便捷性:

提供图形化配置工具与数据日志记录功能,方便故障追溯与趋势分析。

YASKAWA JANCD-CPII is a core control module designed by Yaskawa Electric(YASKAWA)for industrial automation systems.It is a core component of PLC/DCS systems and is widely used in power,automobiles,steel,energy and other fields.The following is an analysis of its comprehensive technical characteristics and application scenarios:

1.Core functions

High reliability control:

As the core module of the PLC system,JANCD-CPII is responsible for logic control,data acquisition and processing,supports real-time response and high-precision execution of complex industrial scenarios,and is suitable for 7×24 hours continuous operation environment.

Multi-protocol compatibility:

Supports industrial communication protocols such as Modbus,Profinet,EtherCAT,etc.,and can seamlessly connect to mainstream control systems such as Siemens and Schneider to achieve data interaction and multi-device collaborative control.

Expansion capabilities:

Provides digital/analog input and output interfaces,supports cascading with servo drives,sensors and robot systems,and meets the expansion needs of distributed systems.

2.Technical features

Industrial-grade protection:

Adopts wide temperature design(-40℃to 70℃),anti-electromagnetic interference capability meets IP20 protection standards,and mean time between failures(MTBF)exceeds 50,000 hours,adapting to harsh industrial environments.

Intelligent diagnosis and maintenance:

Built-in self-check function,supports real-time display of fault codes and remote maintenance,shortens downtime and reduces maintenance costs.

Flexible configuration:

Supports programming languagessuch as ladder diagram(LAD)and function block(FBD),compatible with mainstream configuration software(such as Siemens TIA Portal),lowering the development threshold.

3.Application scenarios

Power industry:

Applied to intelligent substation automation,generator set control,and optimize grid synchronization and power distribution response speed.

Automobile manufacturing:

Drives the logic control unit of robot workstations such as welding and spraying to achieve high-precision positioning and beat optimization.

Steel industry:

Manages process flows such as steelmaking furnace temperature control and rolling mill synchronization to ensure production efficiency and safety.

Energy and Chemical Industry:

Supports gas turbine control,reactor pressure monitoring and other scenarios,and realizes alarm output and exception handling.

4.Technical advantages

Quick deployment:

Built-in standard protocol templates can be quickly integrated into existing automation projects to shorten the implementation cycle.

Modular design:

Supports seamless connection with Yaskawa servo drives(such asΣ-V series)and robot systems to reduce the complexity of system development.

Easy maintenance:

Provides graphical configuration tools and data log recording functions to facilitate fault tracing and trend analysis.