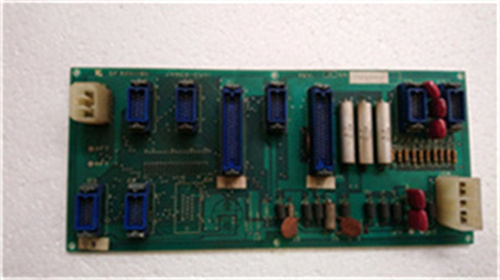

描述

YASKAWA JANCD-CU01是安川电机(YASKAWA)为工业自动化系统设计的核心控制模块,集计量、控制与通信功能于一体,广泛应用于能源、化工、过程控制及智能制造等领域。以下是其综合技术特性与应用场景分析:

1.核心功能

高精度计量与控制:

作为定量给料机(CFW)的核心控制器,集成CFC-200多功能计量模块,采用摩托罗拉68k系列CPU,支持荷重传感器(Loadcell)与变频器(如安川616G5)的协同控制,实现材料流量的精准调度与抗干扰处理,系统精度达±0.2%。

PLC冗余与现场总线通信:

采用三菱MELSEC-A系列PLC双机冗余结构(主PLC1+热备PLC2),支持CC-Link现场总线协议,最大传输速率10Mbps,可连接64个从站设备,如传感器、变频器及触摸屏,确保系统可靠性与扩展性。

Modbus协议兼容性:

上下位机通信采用Modbus RTU协议(RS-485接口),支持CRC差错校验,可与西门子、施耐德等主流控制系统无缝对接,实现数据高效传输与多设备协同作业。

2.技术特点

抗干扰与自诊断:

集成抗干扰电路设计与自诊断功能,可实时检测传感器、变频器及PLC模块的运行状态,主动触发报警并记录故障代码,提升系统稳定性。

机电一体化集成:

与德国SEW高精度变频电机及安川矢量型变频器组成完整闭环控制系统,支持自整定PI调节算法,优化动态响应速度与控制精度。

灵活扩展性:

支持CC-Link总线扩展至13.2km(通过中继器),兼容360+种工业设备(如传感器、触摸屏、调度器),满足复杂工艺流程的扩展需求。

3.应用场景

能源与化工:

应用于煤炭、水泥等行业的定量给料系统,精确控制原料流量,减少损耗并优化生产效率。

过程控制:

驱动食品加工、制药领域的混合、灌装设备,实现物料配比的高精度控制与实时监控。

智能制造:

集成于工业机器人系统,协同控制多轴伺服电机的同步运动与负载自适应调整。

4.技术优势

快速部署:

支持三菱GX Developer 7.0平台梯形图编程,内置网络设备参数自动初始化功能,缩短系统调试周期。

维护便捷性:

提供触摸屏(GOT940)双层监控界面,即使上位机失效,下位机仍可独立运行,减少停机风险。

行业适配性:

YASKAWA JANCD-CU01 is a core control module designed by Yaskawa Electric(YASKAWA)for industrial automation systems.It integrates metering,control and communication functions and is widely used in energy,chemical industry,process control and intelligent manufacturing.The following is an analysis of its comprehensive technical characteristics and application scenarios:

1.Core functions

High-precision metering and control:

As the core controller of the quantitative feeder(CFW),it integrates the CFC-200 multi-function metering module,adopts the Motorola 68k series CPU,supports the coordinated control of load cells and inverters(such as Yaskawa 616G5),realizes the precise scheduling and anti-interference processing of material flow,and the system accuracy reaches±0.2%.

PLC redundancy and fieldbus communication:

Adopts Mitsubishi MELSEC-A series PLC dual-machine redundant structure(main PLC1+hot standby PLC2),supports CC-Link fieldbus protocol,maximum transmission rate of 10Mbps,and can connect 64 slave devices such as sensors,inverters and touch screens to ensure system reliability and scalability.

Modbus protocol compatibility:

The communication between the upper and lower computers adopts Modbus RTU protocol(RS-485 interface),supports CRC error checking,and can be seamlessly connected with mainstream control systems such as Siemens and Schneider to achieve efficient data transmission and multi-device collaborative operation.

2.Technical features

Anti-interference and self-diagnosis:

Integrated anti-interference circuit design and self-diagnosis function can detect the operating status of sensors,inverters and PLC modules in real time,actively trigger alarms and record fault codes to improve system stability.

Mechatronics integration:

Combined with German SEW high-precision variable frequency motors and Yaskawa vector inverters to form a complete closed-loop control system,support self-tuning PI adjustment algorithm,optimize dynamic response speed and control accuracy.

Flexible scalability:

Supports CC-Link bus expansion to 13.2km(through repeaters),compatible with 360+types of industrial equipment(such as sensors,touch screens,schedulers),and meet the expansion needs of complex process flows.

3.Application scenarios

Energy and chemical industry:

Applied to quantitative feeding systems in coal,cement and other industries to accurately control raw material flow,reduce losses and optimize production efficiency.

Process control:

Drives mixing and filling equipment in the food processing and pharmaceutical fields to achieve high-precision control and real-time monitoring of material ratios.

Intelligent manufacturing:

Integrated into industrial robot systems,collaboratively controls the synchronous movement and load adaptive adjustment of multi-axis servo motors.

4.Technical advantages

Quick deployment:

Supports Mitsubishi GX Developer 7.0 platform ladder diagram programming,built-in network device parameter automatic initialization function,shortening the system debugging cycle.

Easy maintenance:

Provides a touch screen(GOT940)double-layer monitoring interface.Even if the upper computer fails,the lower computer can still run independently,reducing the risk of downtime.

Industry adaptability: