描述

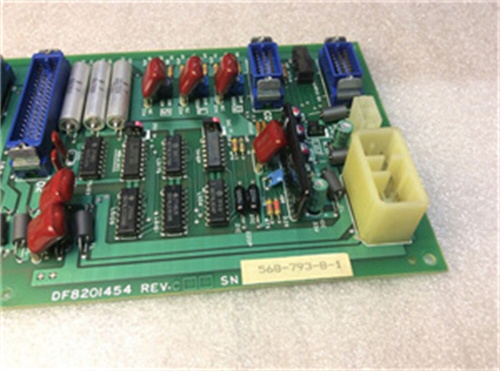

YASKAWA JANCD-CU03是安川电机(YASKAWA)为工业自动化系统设计的高性能控制模块,属于PLC/DCS扩展系列,广泛应用于能源、电力、机器人及智能制造等领域。以下是其综合技术特性与应用场景分析:

1.核心功能

高速逻辑与运动控制:

支持高速输入输出(DI/DO)处理,响应时间<1ms,集成多轴运动控制算法(如插补、电子齿轮),适用于机器人轨迹规划、高速分拣及精密装配等复杂任务。

通信与协议兼容性:

集成MECHATROLINK-III、EtherCAT及Profinet协议,可无缝对接主流机器人控制系统(如安川MOTOMAN)与PLC(如西门子S7),实现数据高效传输与多设备协同控制。

扩展灵活性:

提供8路模拟量输入(AI)与8路模拟量输出(AO)接口,支持与Σ-Ⅴ系列伺服驱动器级联,构建分布式运动控制系统。

2.技术特点

高性能计算:

内置专用运动控制芯片,支持多任务并行处理(如同步控制、数据采集与逻辑运算),适用于高负载工业场景。

工业级可靠性:

采用宽温设计(-40℃至70℃),抗电磁干扰能力符合IP20防护标准,平均无故障时间(MTBF)超50,000小时,满足严苛工业环境需求。

振动抑制技术:

集成改进型算法,可减少伺服系统运行时的机械振动,提升设备稳定性与加工精度,尤其在高动态负载场景中表现突出。

3.应用场景

机器人系统:

驱动工业机器人多轴运动控制单元,实现高速分拣、精密装配及复杂轨迹跟踪(如汽车焊接工作站)。

能源电力:

应用于智能变电站自动化、风电机组控制,优化电网同步与功率分配响应速度。

智能制造:

驱动数控机床伺服系统,实现高精度铣削、磨削等工序的实时调控与负载自适应调整。

轨道交通:

支持列车牵引系统的高速输出控制与冗余设计,确保紧急制动的快速响应。

YASKAWA JANCD-CU03 is a high-performance control module designed by Yaskawa Electric(YASKAWA)for industrial automation systems.It belongs to the PLC/DCS extension series and is widely used in energy,electricity,robotics and intelligent manufacturing.The following is an analysis of its comprehensive technical characteristics and application scenarios:

1.Core functions

High-speed logic and motion control:

Supports high-speed input and output(DI/DO)processing,response time<1ms,integrated multi-axis motion control algorithms(such as interpolation,electronic gears),suitable for complex tasks such as robot trajectory planning,high-speed sorting and precision assembly.

Communication and protocol compatibility:

Integrated MECHATROLINK-III,EtherCAT and Profinet protocols,can seamlessly connect mainstream robot control systems(such as Yaskawa MOTOMAN)and PLCs(such as Siemens S7),and achieve efficient data transmission and multi-device collaborative control.

Expansion flexibility:

Provides 8 analog input(AI)and 8 analog output(AO)interfaces,supports cascading withΣ-V series servo drives,and builds a distributed motion control system.

2.Technical features

High-performance computing:

Built-in dedicated motion control chip,supports multi-task parallel processing(such as synchronous control,data acquisition and logical operation),suitable for high-load industrial scenarios.

Industrial-grade reliability:

Adopts wide temperature design(-40℃to 70℃),anti-electromagnetic interference capability meets IP20 protection standards,and the mean time between failures(MTBF)exceeds 50,000 hours,meeting the needs of harsh industrial environments.

Vibration suppression technology:

Integrated improved algorithm can reduce mechanical vibration during servo system operation,improve equipment stability and processing accuracy,especially in high dynamic load scenarios.

3.Application scenarios

Robotic system:

Drives industrial robot multi-axis motion control unit to achieve high-speed sorting,precision assembly and complex trajectory tracking(such as automotive welding workstations).

Energy and power:

Applied to intelligent substation automation,wind turbine control,and optimizes grid synchronization and power distribution response speed.

Intelligent manufacturing:

Drives CNC machine tool servo system to achieve real-time control and load adaptive adjustment of high-precision milling,grinding and other processes.

Rail transit:

Support high-speed output control and redundant design of train traction systems to ensure rapid response to emergency braking.