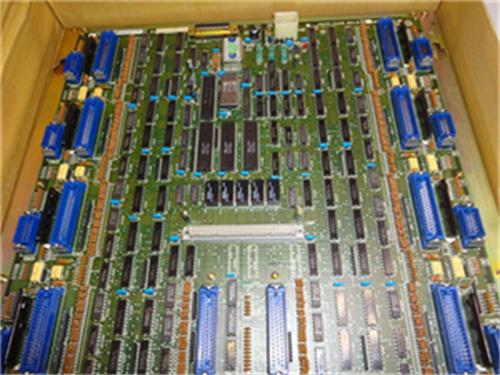

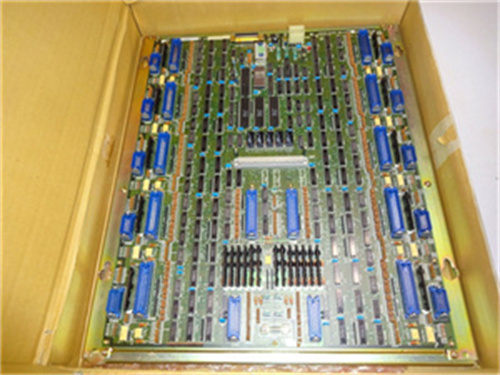

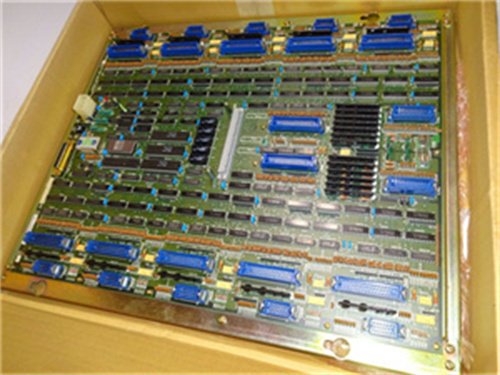

描述

YASKAWA JANCD-CU06是安川电机(YASKAWA)为工业自动化系统设计的高性能控制模块,属于PLC/DCS扩展系列,专注于高精度运动控制与工业互联网集成,广泛应用于半导体制造、医疗设备、精密加工及轨道交通等领域。以下是其综合技术特性与应用场景分析:

1.核心功能

高精度运动控制:

支持多轴同步插补(如直线、圆弧、螺旋插补)、电子齿轮及主从控制,可实现±0.01°定位精度与高速响应(响应时间<1ms),适用于半导体晶圆搬运、医疗影像设备定位等高精度场景。

工业互联网兼容性:

集成EtherCAT、Profinet及OPC UA协议,支持与工业云平台无缝对接,实现数据采集、分析与远程运维,满足智能制造的数字化需求。

扩展灵活性:

提供16路数字量输入/输出与8路模拟量输入接口,支持与Σ-Ⅴ系列伺服驱动器级联,构建分布式运动控制系统。

2.技术特点

高性能计算:

内置双核ARM Cortex-A9处理器,支持多任务并行处理(如逻辑控制、运动算法与数据通信),适用于复杂工业场景的实时计算需求。

工业级防护:

采用宽温设计(-40℃至85℃),抗电磁干扰能力符合IP40防护标准,平均无故障时间(MTBF)超100,000小时,满足极端工业环境需求。

振动抑制与动态补偿:

集成改进型振动抑制算法与负载惯量自适应技术,可减少伺服系统运行时的机械振动,优化精密加工设备的稳定性与重复精度。

3.应用场景

半导体制造:

驱动晶圆传输机械臂的高精度定位与多轴同步控制,提升半导体生产良率与效率。

医疗设备:

应用于CT/MRI扫描仪的运动控制单元,实现影像采集时的精准定位与动态补偿。

精密加工:

驱动数控机床伺服系统,实现复杂曲面加工的高速响应与纳米级精度控制。

轨道交通:

支持列车受电弓升/降控制及转向架振动抑制,确保高速运行时的稳定性与安全性。

YASKAWA JANCD-CU06 is a high-performance control module designed by Yaskawa Electric for industrial automation systems.It belongs to the PLC/DCS extension series and focuses on high-precision motion control and industrial Internet integration.It is widely used in semiconductor manufacturing,medical equipment,precision machining and rail transportation.The following is an analysis of its comprehensive technical characteristics and application scenarios:

1.Core functions

High-precision motion control:

Supports multi-axis synchronous interpolation(such as linear,circular,and spiral interpolation),electronic gears,and master-slave control,which can achieve±0.01°positioning accuracy and high-speed response(response time<1ms),suitable for high-precision scenarios such as semiconductor wafer handling and medical imaging equipment positioning.

Industrial Internet compatibility:

Integrated with EtherCAT,Profinet and OPC UA protocols,supports seamless docking with industrial cloud platforms,realizes data collection,analysis and remote operation and maintenance,and meets the digital needs of intelligent manufacturing.

Expansion flexibility:

Provides 16 digital input/output and 8 analog input interfaces,supports cascading withΣ-V series servo drives,and builds a distributed motion control system.

2.Technical Features

High-performance computing:

Built-in dual-core ARM Cortex-A9 processor,supports multi-task parallel processing(such as logic control,motion algorithm and data communication),suitable for real-time computing needs in complex industrial scenarios.

Industrial-grade protection:

Adopts wide temperature design(-40℃to 85℃),anti-electromagnetic interference capability meets IP40 protection standard,and mean time between failures(MTBF)exceeds 100,000 hours,meeting the needs of extreme industrial environments.

Vibration suppression and dynamic compensation:

Integrated improved vibration suppression algorithm and load inertia adaptive technology can reduce mechanical vibration during servo system operation and optimize the stability and repeatability of precision machining equipment.

3.Application scenarios

Semiconductor manufacturing:

Drives high-precision positioning and multi-axis synchronous control of wafer transfer robot arms to improve semiconductor production yield and efficiency.

Medical equipment:

Motion control unit used in CT/MRI scanners to achieve precise positioning and dynamic compensation during image acquisition.

Precision machining:

Drives CNC machine tool servo system to achieve high-speed response and nanometer-level precision control of complex surface machining.

Rail transit:

Supports pantograph raising/lowering control and bogie vibration suppression to ensure stability and safety during high-speed operation.