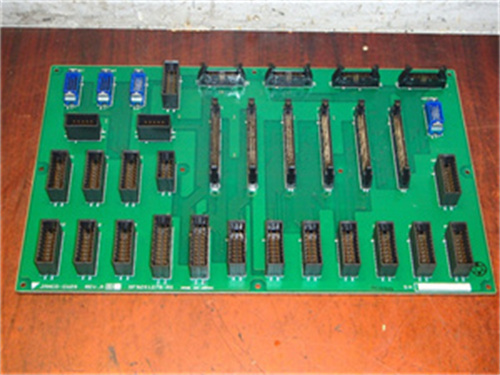

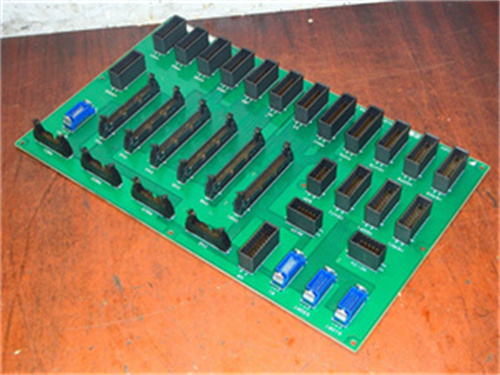

描述

YASKAWA JANCD-CU20是安川电机(YASKAWA)为工业自动化系统设计的高端控制模块,结合AI边缘计算与工业互联网技术,广泛应用于半导体制造、医疗设备、精密加工及智能物流等领域。以下是其综合技术特性与应用场景分析:

1.核心功能

AI边缘计算集成:

内置边缘计算单元,支持TensorFlow Lite等轻量级AI框架,可实现本地化数据分析与实时决策,如设备预测性维护、异常模式识别及动态参数优化。

高精度运动控制:

支持多轴同步插补(±0.005°定位精度)与电子凸轮控制,适用于半导体晶圆传输、医疗影像设备定位及精密加工等场景。

工业互联网协议兼容性:

集成OPC UA、MQTT及5G通信模块,支持与云端平台无缝对接,实现远程运维、数据可视化与协同生产。

2.技术特点

高性能计算:

配备NVIDIA Jetson系列边缘AI芯片,算力达15 TOPS,支持多任务并行处理(如逻辑控制、AI推理与运动算法),适用于复杂工业场景的实时计算需求。

工业级防护与可靠性:

采用宽温设计(-40℃至85℃),抗电磁干扰能力符合IP54防护标准,平均无故障时间(MTBF)超150,000小时,满足极端工业环境需求。

动态自适应控制:

集成负载惯量自适应算法与振动抑制技术,可自动调整伺服参数以应对负载变化,优化设备稳定性与加工精度。

3.应用场景

半导体制造:

驱动晶圆传输机械臂的高精度定位与多轴协同控制,结合AI算法实现晶圆缺陷实时检测与工艺参数优化。

医疗设备:

应用于手术机器人运动控制单元,实现动态补偿与人机交互安全防护。

智能物流:

驱动AGV小车的路径规划与避障决策,结合5G通信实现多车协同作业。

精密加工:

驱动五轴联动机床,实现复杂曲面加工的纳米级精度控制与刀具寿命预测。

4.技术优势

模块化冗余设计:

支持PLC双机热备(主/从模式)与数据实时同步,适用于医疗设备、轨道交通等高可靠性场景。

快速部署与调试:

提供图形化配置工具与自动整定功能(整定时间<20ms),支持与TIA Portal等组态软件无缝对接。

维护便捷性:

集成预测性维护模块,通过AI分析设备运行数据并提前预警故障,减少停机时间。

YASKAWA JANCD-CU20 is a high-end control module designed by Yaskawa Electric for industrial automation systems.It combines AI edge computing with industrial Internet technology and is widely used in semiconductor manufacturing,medical equipment,precision machining and intelligent logistics.The following is an analysis of its comprehensive technical characteristics and application scenarios:

1.Core functions

AI edge computing integration:

Built-in edge computing unit,supports lightweight AI frameworks such as TensorFlow Lite,and can realize localized data analysis and real-time decision-making,such as equipment predictive maintenance,abnormal pattern recognition and dynamic parameter optimization.

High-precision motion control:

Supports multi-axis synchronous interpolation(±0.005°positioning accuracy)and electronic cam control,suitable for semiconductor wafer transmission,medical imaging equipment positioning and precision machining.

Industrial Internet protocol compatibility:

Integrated OPC UA,MQTT and 5G communication modules,support seamless docking with cloud platforms,and realize remote operation and maintenance,data visualization and collaborative production.

2.Technical Features

High-performance computing:

Equipped with NVIDIA Jetson series edge AI chips,the computing power reaches 15 TOPS,supports multi-task parallel processing(such as logic control,AI reasoning and motion algorithms),and is suitable for real-time computing needs in complex industrial scenarios.

Industrial-grade protection and reliability:

Adopting a wide temperature design(-40℃to 85℃),the anti-electromagnetic interference capability meets the IP54 protection standard,and the mean time between failures(MTBF)exceeds 150,000 hours,meeting the needs of extreme industrial environments.

Dynamic adaptive control:

Integrated load inertia adaptive algorithm and vibration suppression technology,which can automatically adjust servo parameters to cope with load changes and optimize equipment stability and processing accuracy.

3.Application scenarios

Semiconductor manufacturing:

Drives high-precision positioning and multi-axis collaborative control of wafer transfer robotic arms,and combines AI algorithms to achieve real-time detection of wafer defects and process parameter optimization.

Medical equipment:

Applied to surgical robot motion control units to achieve dynamic compensation and human-machine interaction safety protection.

Intelligent logistics:

Drives the path planning and obstacle avoidance decision-making of AGV vehicles,and combines 5G communications to achieve multi-vehicle collaborative operations.

Precision machining:

Drives five-axis linkage machine tools to achieve nano-precision control and tool life prediction for complex surface machining.

4.Technical advantages

Modular redundant design:

Supports PLC dual-machine hot standby(master/slave mode)and real-time data synchronization,suitable for high-reliability scenarios such as medical equipment and rail transit.

Quick deployment and debugging:

Provides graphical configuration tools and automatic tuning functions(tuning time<20ms),and supports seamless docking with configuration software such as TIA Portal.

Convenient maintenance:

Integrated predictive maintenance module,analyzes equipment operation data through AI and warns of faults in advance,reducing downtime.