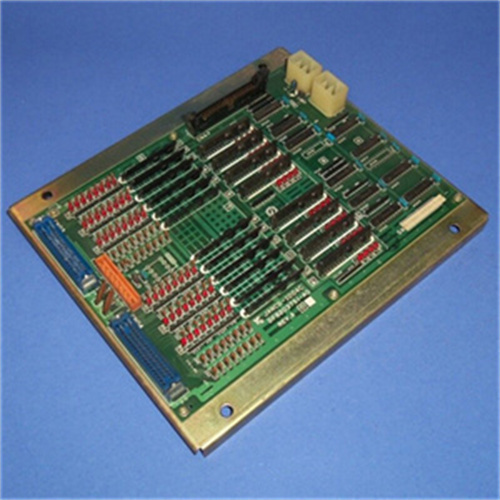

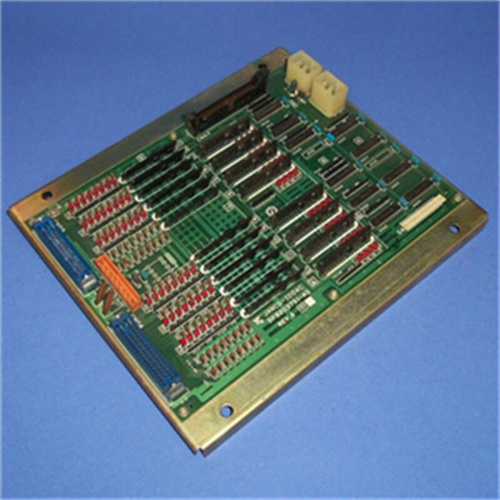

描述

YASKAWA CIMR-HB4A0450ABC是安川电机(YASKAWA)旗下H1000系列高性能重载变频器的典型型号,专为工业自动化领域设计,适用于高负载、高精度控制场景。以下是其核心产品特性与技术参数的综合概述:

一、型号与功率参数

型号:CIMR-HB4A0450ABC

功率范围:220 kW(超重载/220 kW)

防护等级:IP00(非防护型),适用于室内安装环境

二、核心性能特点

高扭矩控制

-支持矢量控制模式,可实现±5%的高精度转矩控制,适用于感应电机与永磁同步电机。

-集成转矩限制功能,可保护机械免受突发负载冲击,确保运行安全。

高速响应与稳定性

-带PG(编码器)反馈时,速度响应可达50 Hz以上,适用于高速定位与动态负载场景。

-通过前馈补偿功能,可抑制机械振动与过冲,优化加减速过程。

通信与扩展能力

-标准配备RS-422/485通信接口,支持Modbus等协议。

-支持扩展PROFIBUS-DP、DeviceNet、CC-Link等工业现场总线,便于多设备协同控制。

环保与节能设计

-符合RoHS指令,采用Swing PWM技术降低电磁干扰与噪音。

-长寿命设计(10年),同步电机轴承寿命约为传统电机的2倍。

三、应用场景

升降机械:起重机、升降平台等重载设备的精准速度与位置控制。

流体机械:泵、风机等设备的流量与压力调节。

金属加工:机床、切割机等高精度加工设备的动力驱动。

搬运机械:AGV、传送带等自动化物流系统的速度与负载匹配。

四、设计与维护优势

用户友好性

-配备DriveWorksEZ可视化编程软件,支持参数自动优化与USB接口数据传输。

-支持参数备份与端子排可拆卸设计,简化维护与故障诊断流程。

安全与可靠性

-符合EN954-1 Cat.3及IEC/EN61508 SIL2安全标准。

-集成制动电阻过温保护、停电安全停止(KEB功能)等安全机制。

五、技术规格补充

电压等级:380 V AC(400 V级)

安装方式:标准机柜安装

环境适应性:工作温度范围-10℃至+55℃。

YASKAWA CIMR-HB4A0450ABC is a typical model of the H1000 series of high-performance heavy-duty inverters under YASKAWA Electric(YASKAWA).It is designed for the field of industrial automation and is suitable for high-load and high-precision control scenarios.The following is a comprehensive overview of its core product features and technical parameters:

I.Model and power parameters

Model:CIMR-HB4A0450ABC

Power range:220 kW(super heavy load/220 kW)

Protection level:IP00(non-protective type),suitable for indoor installation environment

II.Core performance characteristics

High torque control

-Support vector control mode,which can achieve high-precision torque control of±5%,suitable for induction motors and permanent magnet synchronous motors.

-Integrated torque limit function can protect the machine from sudden load shocks and ensure safe operation.

High-speed response and stability

-With PG(encoder)feedback,the speed response can reach more than 50 Hz,which is suitable for high-speed positioning and dynamic load scenarios.

-Through the feedforward compensation function,mechanical vibration and overshoot can be suppressed to optimize the acceleration and deceleration process.

Communication and expansion capabilities

-Standard RS-422/485 communication interface,supporting Modbus and other protocols.

-Supports expansion of industrial fieldbuses such as PROFIBUS-DP,DeviceNet,CC-Link,etc.,to facilitate collaborative control of multiple devices.

Environmental protection and energy-saving design

-Compliant with the RoHS directive,using Swing PWM technology to reduce electromagnetic interference and noise.

-Long life design(10 years),the bearing life of synchronous motors is about twice that of traditional motors.

III.Application scenarios

Lifting machinery:Precise speed and position control of heavy-duty equipment such as cranes and lifting platforms.

Fluid machinery:Flow and pressure regulation of equipment such as pumps and fans.

Metal processing:Power drive of high-precision processing equipment such as machine tools and cutting machines.

Handling machinery:Speedand load matching of automated logistics systems such as AGV and conveyor belts.

IV.Design and maintenance advantages

User-friendliness

-Equipped with DriveWorksEZ visual programming software,supporting automatic parameter optimization and USB interface data transmission.

-Supports parameter backup and detachable terminal block design to simplify maintenance and fault diagnosis processes.

Safety and reliability

-Complies with EN954-1 Cat.3 and IEC/EN61508 SIL2 safety standards.

-Integrated safety mechanisms such as brake resistor overtemperature protection and power failure safety stop(KEB function).

V.Technical Specifications

Voltage level:380 V AC(400 V level)

Installation method:standard cabinet installation

Environmental adaptability:Operating temperature range-10℃to+55℃.