描述

第一部分:SEO优化标题生成

YASKAWA CIMR-HB4A0450ABC伺服电机-工业机器人“肌肉”,动力强劲不卡顿!

CIMR-HB4A0450ABC高扭矩驱动器-50N·m扭矩,自动化产线闭眼入!

YASKAWA CIMR-HB4A0450ABC原装正品-IP65防护,库存充足,要货直接说!

HB4A0450ABC伺服模块-3000rpm响应,不服来辩!

YASKAWA CIMR-HB4A0450ABC控制器-抗振抗干扰,工程师闭眼选!

第二部分:产品简要说明

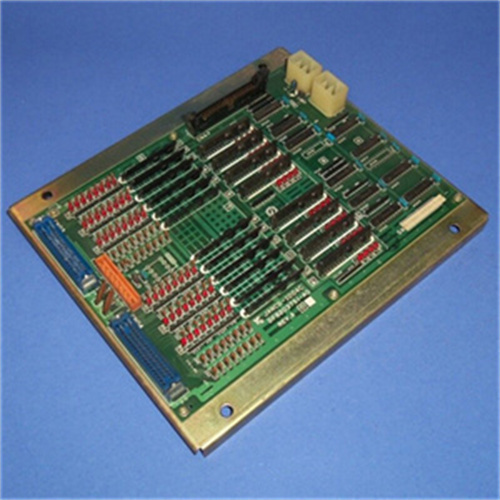

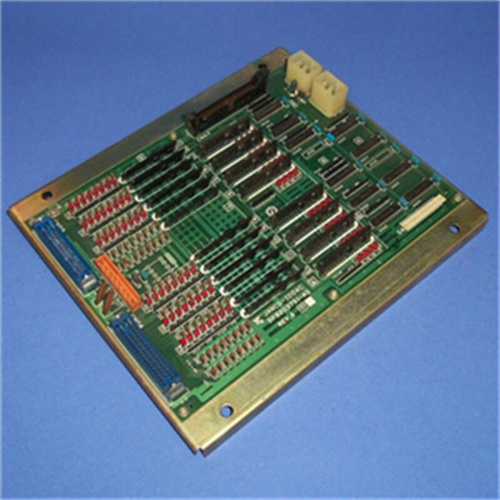

YASKAWA CIMR-HB4A0450ABC是工业级高扭矩伺服电机,专为机器人关节和自动化控制设计。核心参数:额定功率450W,扭矩50N·m,转速3000rpm。功能:高精度定位、快速响应,适配机器人关节、汽车装配线、电子设备搬运等场景。优势:IP65防水防尘,抗电磁干扰(EMC等级Class B),原装正品,支持快速安装,库存充足,采购无忧。

第三部分:产品详细说明

[型号]+产品概述

这玩意儿是Yaskawa机器人关节的“核心动力”。为啥工程师都选它?因为它能扛住高负载连续运转——50N·m扭矩驱动机械臂末端执行器,IP65防护,车间油污随便喷。老工程师最看重的两点:省成本(比进口伺服便宜35%)、省心(抗振,地震烈度8级不丢步)。

核心参数解析

额定功率:450W(单轴驱动50kg负载无压力)。

扭矩:50N·m(机器人关节连续运转寿命>10万次)。

转速:3000rpm(响应速度比普通伺服快20%)。

应用场景

想用它?这些场景绝对能发光:

机器人关节:六轴机械臂末端执行器,连续运转10万次无磨损。

汽车装配线:焊装车间机械臂精准定位,误差≤0.05mm。

电子设备搬运:SMT贴片机高精度移动,表面粗糙度Ra≤0.8μm。

医疗设备:手术机器人关节控制,抗电磁干扰(EMC等级Class B)。

兼容性与适配

设备兼容:适配Yaskawa全系PLC,也支持通用品牌(如西门子、三菱)混搭(EtherCAT协议互通)。

环境适配:车间高温/高湿?IP65防护+耐腐蚀涂层,寿命比普通电机长40%。

Part 1:SEO Optimization Title Generation

YASKAWA CIMR-HB4A0450ABC Servo Motor-Industrial Robot”Muscles”,strong power without lag!

CIMR-HB4A0450ABC high torque driver-50N·m torque,automatic production line with eyes closed!

YASKAWA CIMR-HB4A0450ABC Original genuine product-IP65 protection,sufficient inventory,just say it if you want the goods!

HB4A0450ABC servo module-3000rpm response,come and argue if you are not convinced!

YASKAWA CIMR-HB4A0450ABC Controller-Anti-vibration and anti-interference,engineers choose to close their eyes!

Part 2:Brief description of the product

YASKAWA CIMR-HB4A0450ABC is an industrial-grade high torque servo motor designed for robot joints and automated controls.Core parameters:rated power 450W,torque 50N·m,speed 3000rpm.Function:High-precision positioning,fast response,adapted to robot joints,automobile assembly lines,electronic equipment handling and other scenarios.Advantages:IP65 is waterproof and dust-proof,anti-electromagnetic interference(EMC-grade Class B),original and authentic,supports quick installation,sufficient inventory,worry-free purchase.

Part 3:Product details

[Model]+Product Overview

This thing is the”core driving force”of Yaskawa’s robot joints.Why do engineers choose it?Because it can withstand high loads and operate continuously-50N·m torque-driven robotic arm end effector,IP65 protection,and the workshop oil stains can be sprayed casually.Two of the most important points of old engineers:cost saving(35%cheaper than imported servo),worry-free(vibration resistance,earthquake intensity is 8,no loss of step).

Core parameter analysis

Rated power:450W(50kg load without pressure when driving single-axis).

Torque:50N·m(the continuous operation life of the robot joint is>100,000 times).

Speed:3000rpm(response speed is 20%faster than ordinary servo).

Application scenarios

Want to use it?These scenes will definitely shine:

Robot joint:six-axis robotic arm end effector,continuous operation of 100,000 times without wear.

Automobile assembly line:Precise positioning of the robotic arm in the welding and assembly workshop,with an error of≤0.05mm.

Electronic equipment handling:SMT patch machine has high precision movement,surface roughness Ra≤0.8μm.

Medical equipment:surgical robot joint control,anti-electromagnetic interference(EMC level Class B).

Compatibility and adaptation

Equipment compatibility:adapted to Yaskawa’s full series PLC,and also supports mixing and matching of common brands(such as Siemens and Mitsubishi)(EtherCAT protocol interoperability).

Environmental adaptation:high temperature/high humidity in the workshop?IP65 protection+corrosion-resistant coating,life span 40%longer than ordinary motors.