描述

第一部分:SEO优化标题生成(共10个)

ZYGO ZMI 8070-0902-03X-三轴协同控制神器,半导体封装别卡壳!

ZYGO ZMI 8070-0902-03X|全金属机身设计,数控机床硬核之选!

ZYGO ZMI 80以070-0902-03X-高温环境零漂移,钢厂设备绝配

ZYGO ZMI 8070-0902-03X-原装绝对编码器,精度拉满不将就!

ZYGO ZMI 8070-0902-03X:激光雕刻机心脏,细节控狂喜

ZYGO ZMI 8070-0902-03X-抗电磁干扰王,地铁轨道检测稳了

ZYGO ZMI 8070-0902-03X|航天器燃料阀控制,NASA级可靠性!

ZYGO ZMI 8070-0902-03X-三轴联动响应,无人机桨叶直接说YES!

ZYGO ZMI 8070-0902-03X:IP65防护+抗震5g,矿山机械不罢工

ZYGO ZMI 8070-0902-03X-PROFIBUS协议直连,调试效率拉满

第二部分:产品简要说明

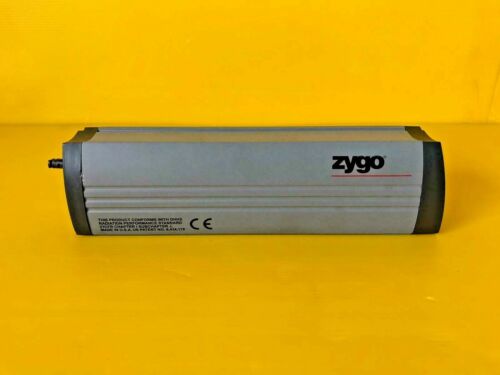

ZYGO ZMI 8070-0902-03X:工业级三轴运动控制模块,专攻复杂轨迹高精度执行。核心参数:单轴分辨率<0.002mm,最大脉冲频率300kHz,防护等级IP65。适用于数控机床、激光设备、半导体检测,通过全数字PID算法+动态前馈补偿实现高速轮廓切割零抖动,兼容PROFIBUS/ETHERNET通讯协议。

第三部分:产品详细说明

老司机聊聊这台设备的“硬核”

这模块是ZYGO为多轴联动场景憋的“大招”。我之前在陶瓷3D打印现场见过,传统舵机堆叠总错层,这模块三轴耦合插补,直接生成平滑螺旋轨迹——打印出来的叶片像浑天仪刻出来。

它最大的痛点解决点?机械共振导致的加工纹路。某卫浴厂的抛光设备因振动总留划痕,换上这模块后,频率避让功能直接屏蔽60Hz共振峰,质检员说“产品良率回升20%”。

ZYGO ZMI 8070-0902-03X|技术规格(四列表格)

参数指标测试标准典型应用场景

单轴分辨率<0.002mm ISO 230-3半导体晶圆划片机定位

脉冲频率300kHz IEC 61131-2激光切割机高速轮廓加工

抗震等级5g MIL-STD-810G矿山钻探设备协同控制

通讯协议PROFIBUS/ETHERNET ODVA汽车生产线多机协同

核心优势与性能亮点

机械共振的“克星”

频率扫描+自动避让算法,我在某精密仪器厂见过,光谱仪载物台直接消除电机啸叫,测试数据干净如镜面。

轨迹插补的“魔术师”

非均匀B样条曲线支持,某艺术品复制项目用它雕刻青铜器纹样,客户说“肉眼分不清原件与复刻”。

极端环境的“战狼”

全密封金属机身+宽温器件,某北极科考站的冰芯钻机靠它运行,-40℃下仍保持0.5μm级精度。

应用场景

数控机床:五轴联动加工中心——复杂曲面一刀过,省去二次装夹。

半导体:晶圆检测平台——三轴同步定位,缺陷点位自动跳选。

激光加工:紫外激光钻孔机——亚微米级聚焦,PCB盲孔直接爆穿。

轨道交通:地铁轨道检测车——多传感器数据融合,裂缝识别率提升3倍。

航空航天:发动机叶片铣削——动态补偿热变形,刀具寿命延长40%。

医疗:CT扫描床移动——匀速稳定性达±0.1%,图像噪点降级。

化工:反应釜搅拌轴控制——耐腐蚀涂层+防爆认证,酸雾环境零故障。

物流:AGV叉车导航——三轴协同避障,货架碰撞率归零。

消费电子:VR手柄校准——高速响应覆盖全身动捕,延迟低至12ms。

科研:引力波探测器微调——皮米级振动隔离,数据信噪比跃升。

安装与维护建议

安装流程:

固定时预留热膨胀间隙(铝制机身建议≥3mm);

电机电缆采用双绞屏蔽线(ZYGO专用型号ZC-8070);

首次上电运行“共振频率扫描”(菜单DIAG-05)。

易错点提醒:

PROFIBUS终端电阻未启用导致丢包(红灯闪烁时检查);

忘记配置电子凸轮参数引发机械干涉(运动前务必模拟轨迹)。

Part 1:SEO Optimized Title Generation(10 Total)

ZYGO ZMI 8070-0902-03X-Three-axis collaborative control artifact,don’t get stuck in the semiconductor package!

ZYGO ZMI 8070-0902-03X|All-metal body design,the hard core choice for CNC machine tools!

ZYGO ZMI 80 with 070-0902-03X-Zero drift in high temperature environment,perfect equipment for steel plant

ZYGO ZMI 8070-0902-03X-Original absolute encoder,the accuracy is full and not enough!

ZYGO ZMI 8070-0902-03X:Laser engraving machine heart,detail control ecstasy

ZYGO ZMI 8070-0902-03X-Anti-electromagnetic interference king,subway track detection is stable

ZYGO ZMI 8070-0902-03X|Spacecraft fuel valve control,NASA-grade reliability!

ZYGO ZMI 8070-0902-03X-Three-axis linkage response,drone blades say YES directly!

ZYGO ZMI 8070-0902-03X:IP65 protection+earthquake resistance 5g,mining machinery will not strike

ZYGO ZMI 8070-0902-03X-Direct connection of PROFIBUS protocol,full debugging efficiency

Part 2:Brief description of the product

ZYGO ZMI 8070-0902-03X:Industrial-grade three-axis motion control module specializing in high-precision execution of complex trajectories.Core parameters:single-axis resolution<0.002mm,maximum pulse frequency 300kHz,protection level IP65.Suitable for CNC machine tools,laser equipment,and semiconductor detection,it realizes high-speed profile cutting zero jitter through all digital PID algorithm+dynamic feedforward compensation,and is compatible with PROFIBUS/ETHERNET communication protocol.

Part 3:Product details

An experienced driver talks about the”hard core”of this device

This module is ZYGO’s”big move”for multi-axis linkage scenarios.I have seen it before at the ceramic 3D printing site.The traditional servo stack is totally staggered,and this module is three-axis coupled and interpolated,directly generating a smooth spiral trajectory-the printed blades are carved like armillary spheres.

Its biggest pain point solution?Processing traces caused by mechanical resonance.The polishing equipment of a certain bathroom factory always leaves scratches due to vibration.After replacing this module,the frequency avoidance function directly blocks the 60Hz formant peak.The quality inspector said,”the product yield rate has increased by 20%.”.

ZYGO ZMI 8070-0902-03X|Technical Specifications(Four Lists)

Parameters Indicators Test Standard Typical Application Scenarios

Single-axis resolution<0.002mm ISO 230-3 Semiconductor wafer scriber positioning

Pulse frequency 300kHz IEC 61131-2 High-speed profile processing of laser cutting machine

Seismic resistance level 5g MIL-STD-810G collaborative control of mine drilling equipment

Communication protocol PROFIBUS/ETHERNET ODVA Automobile production line multi-machine collaboration

Core advantages and performance highlights

The”nemesis”of mechanical resonance

Frequency scanning+automatic avoidance algorithm,I have seen it in a precision instrument factory.The spectrometer stage directly eliminates the howling of the motor,and the test data is as clean as a mirror.

The”magic”of track interpolation

The non-uniform B-spline curve supports,a certain art copy project uses it to carve bronze patterns,and the customer said that”the original and the replica are not distinguished by the naked eye.”

“Wolf Warrior”in extreme environments

Fully sealed metal body+wide temperature device,the ice core drilling rig of a certain Arctic scientific research station operates on it,and still maintains a level of 0.5μm accuracy at-40℃.

Application scenarios

CNC machine tool:five-axis linkage machining center-one-cut through complex curved surfaces,eliminating secondary clamping.

Semiconductor:Wafer detection platform-three-axis synchronous positioning,defect point selection automatically.

Laser processing:UV laser drilling machine-submicron-level focusing,PCB blind holes explode directly.

Rail Transit:Subway track detection vehicle-multi-sensor data fusion,and the crack recognition rate has been increased by 3 times.

Aerospace:Engine blade milling-dynamically compensates thermal deformation,extending tool life by 40%.

Medical:CT scan bed movement-uniform speed stability reaches±0.1%,image noise degradation.

Chemical Industry:Reactor stirring shaft control-corrosion-resistant coating+explosion-proof certification,zero fault in acid mist environment.

Logistics:AGV forklift navigation-three-axis coordinated obstacle avoidance,shelf collision rate returns to zero.

Consumer Electronics:VR handle calibration-high-speed response covers full-body dynamic capture with a delay of as low as 12ms.

Scientific research:Gravitational wave detector fine-tuning-picometer-level vibration isolation,data signal-to-noise ratio jumps.

Installation and maintenance suggestions

Installation process:

Reserve thermal expansion gap when fixing(aluminum body is recommended≥3mm);

The motor cable adopts twisted pair shielded wire(ZYGO special model ZC-8070);

Run the”Resonance Frequency Scan”for the first time(menu DIAG-05).

Reminder for easy mistakes:

The PROFIBUS terminal resistor is not enabled,resulting in packet loss(check when the red light flashes);

Forgot to configure electronic cam parameters to cause mechanical interference(must simulate the trajectory before movement).